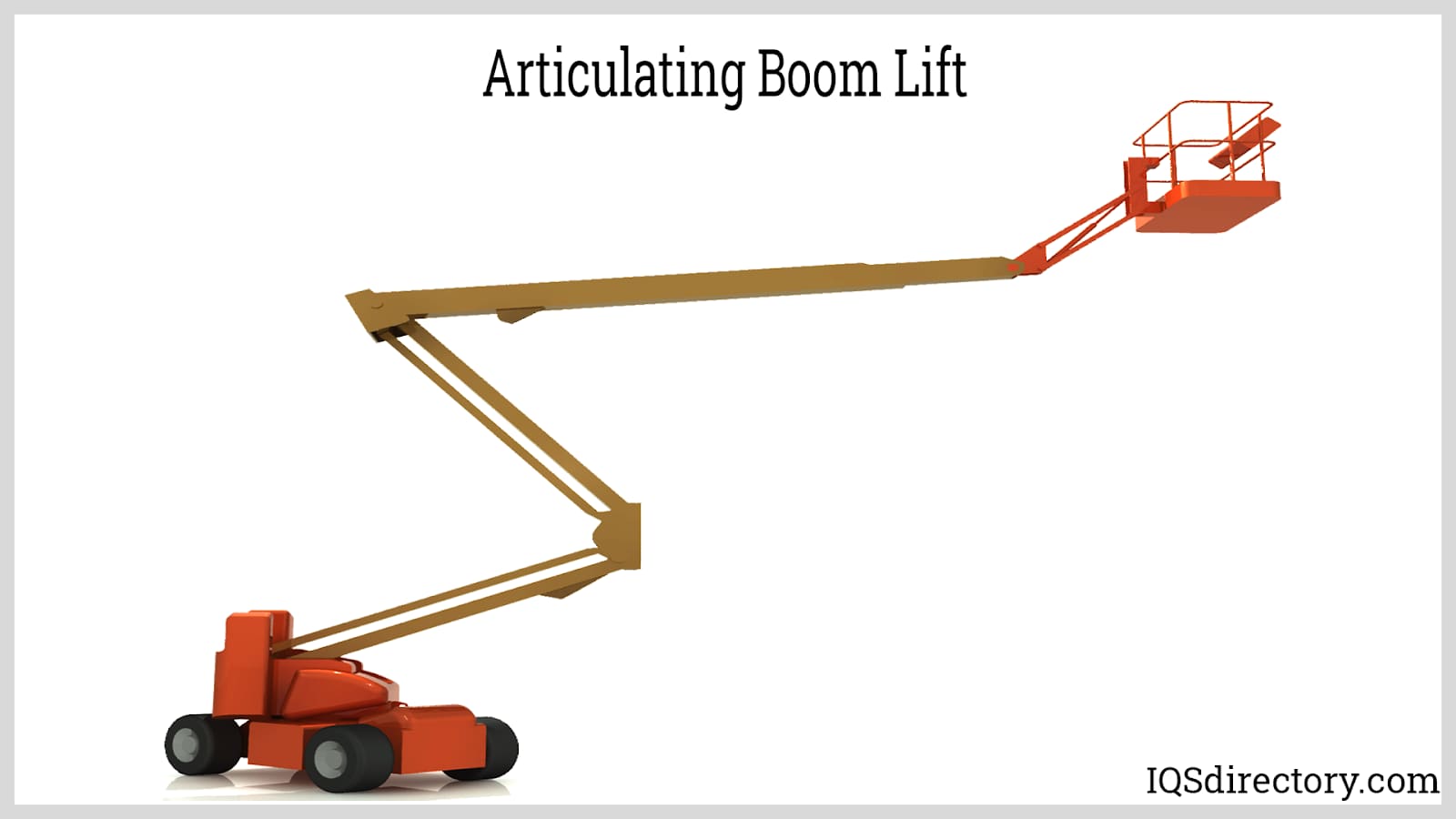

Platform lifts are mechanical lifting devices that utilize a series of telescopically extending arms that are hydraulically powered to raise a platform to great heights. A platform lift consists of a stabilizing base from which the arms of the lift originate. Read More…

Our hydraulic lifts are manufactured using a combination of innovation, state of the art technology, the latest engineering designs, and the highest quality products.

Advance Lifts designs & manufactures hydraulic lifts and other models of material handling equipment. Our ultra high-cycle lifts have a 3,000,000 cycle warranty & our patented platform centering devices reduce lift wear from off centered loading.

We manufacture hydraulic lifts and a whole lot more. Our goal is to be the best in both quality and customer service. In fact, our mission statement stays we will work hard so you can live easier.

We have a wide line of vertical lifts, but customize each product for our customers’ specific applications. Vertical Reciprocating Conveyors--VRCs are for material handling only and can not be used to transport people.

Our hydraulic lifts are a testament to our unwavering commitment to quality and durability. Crafted with exceptional engineering, each product showcases innovative ideas that push the boundaries of what material handling equipment can achieve. We take pride in the heavy-duty materials we utilize, ensuring that our hydraulic lifts meet and exceed the demands of diverse industries.

At Metro Hydraulic Jack, we have been distributing pneumatic, hydraulic and mechanical equipment and tools since 1941. Our product lines include automotive lubrication systems, hydraulic tools for construction, hydraulic lifts and similar types of material handling equipment, mobile hydraulic motors and railroad lifting equipment. We also service most lines of equipment.

Isotech is a distributor of hydraulic lifts and telescopic lifting columns for medical, radiological, and industrial applications. Our columns provide a stable, reliable, and maintenance free guiding system without any play. We can customize the load, speed, and travel to meet your individual application requirements.

More Platform Lift Manufacturers

What are Platform Lifts?

Platform lifts, also referred to as vertical platform lifts (VPLs), are mechanical devices designed to move people, equipment, and goods vertically between different levels. These lifts play a crucial role in enhancing accessibility, safety, and efficiency in a variety of settings including industrial facilities, warehouses, commercial buildings, and residential spaces. Platform lifts are engineered for easy installation and can be customized to fit specific operational requirements.

The base of a platform lift is commonly mounted on a large truck or stationary foundation for stability and easy transportation. The lift arms extend upwards, often terminating in a platform or bucket. Many platform lifts feature a base-mounted control panel, allowing operators to manage the lift’s movement with precision and safety. This user-friendly control system enables seamless vertical mobility, essential for operations at elevated heights.

Platform lifts are frequently utilized for the vertical transportation of packages, materials, and personnel across various heights. Their primary use cases include industrial and commercial applications that demand reliable access to high-altitude workspaces, such as maintenance, repair, construction, and logistics. By providing safe and controlled movement between floors or elevated platforms, platform lifts significantly reduce workplace accidents and improve operational efficiency.

Types of Platform Lifts

When evaluating platform lift solutions for your facility or project, it’s important to understand the different types of lifts available, each designed to address specific needs and applications. Below, we outline the most common types of platform lifts, highlighting their features, industry uses, and advantages.

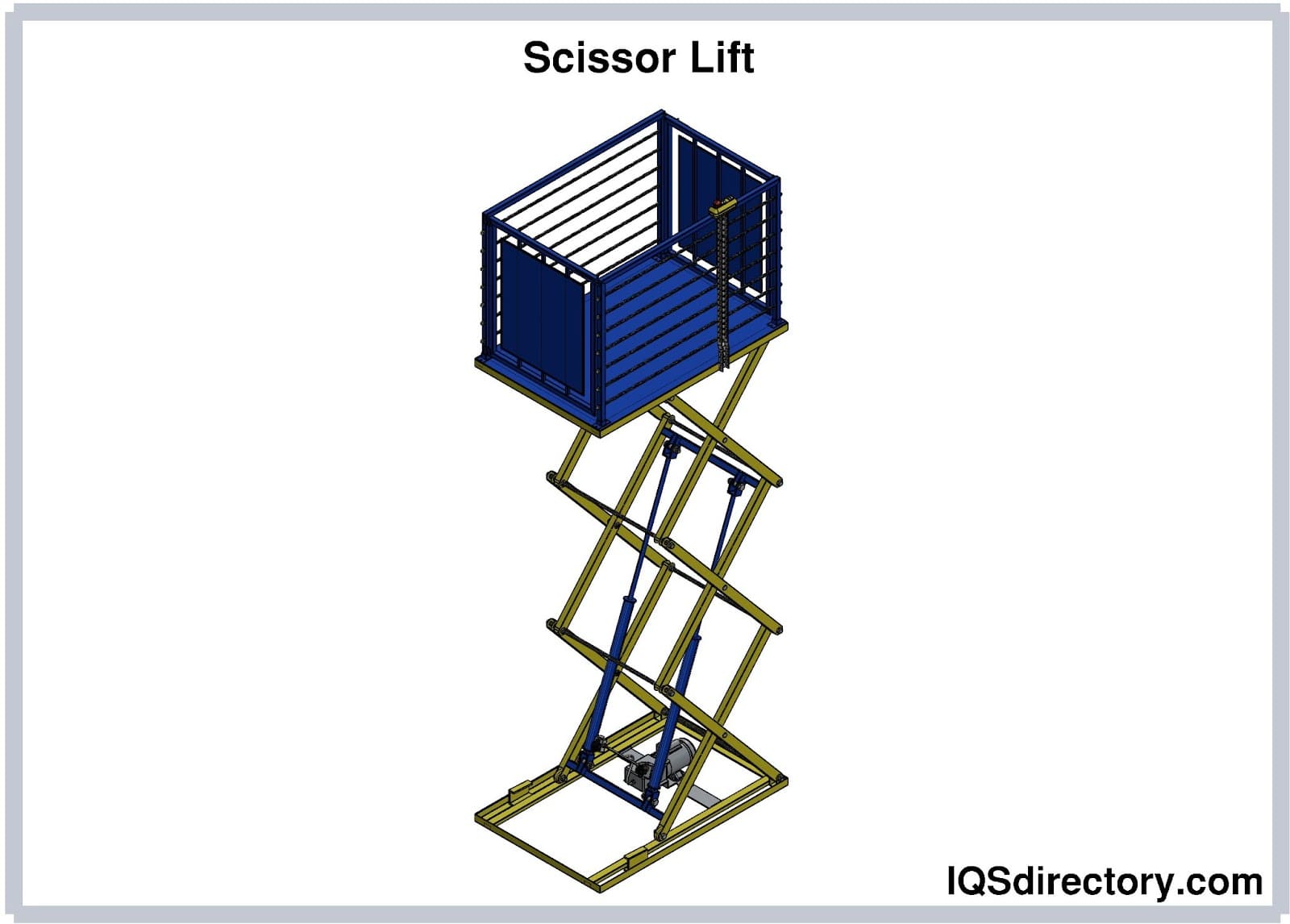

Hydraulic Scissor Lift

The hydraulic scissor lift is one of the most versatile and widely used platform lifts across multiple industries, such as aerospace, entertainment, energy production, automotive manufacturing, and transportation. Its unique scissor mechanism provides stable vertical movement and can accommodate both people and heavy equipment.

The base of the hydraulic scissor lift provides a solid foundation, ensuring the lift remains steady during operation. Powered by one to three hydraulic cylinders, these lifts offer smooth, controlled elevation and descent. A reliable power source or electric motor energizes the hydraulic system, moving the lift vertically with precision.

Hydraulic scissor lifts feature a robust platform at the top, connected to the scissor-like support structure. This design ensures the platform remains parallel to the ground throughout its movement, providing a safe and balanced surface for operators and cargo. The lift’s operation relies on the principles of hydraulic fluid dynamics, which enable the controlled filling and emptying of the lift’s cylinders.

Typical scissor lift applications include:

- Warehouse inventory management

- Construction site access

- Maintenance of lighting, signage, and HVAC systems

- Assembly line workstations

- Automotive repair and detailing

Looking to compare hydraulic scissor lifts for your operation? Ask yourself:

- What is the maximum lifting height and load capacity you require?

- Will the lift be used indoors, outdoors, or in both environments?

- Do you need a mobile or stationary platform lift solution?

The Cylinder-Cylinder Aerial Work Platform

The cylinder-cylinder aerial work platform employs a multi-stage hydraulic cylinder system to raise goods and personnel vertically. Manufactured from high-strength materials, these lifts offer exceptional mechanical performance and superior stability, even at extended heights. The inclusion of a tower-shaped guard frame enhances safety, making these lifts ideal for elevated tasks where stability is paramount.

Cylinder-cylinder aerial work platforms are commonly deployed in environments that require regular access to high-altitude locations, such as docks, railway stations, airports, and public buildings. Their robust design ensures reliable performance in demanding applications.

Key features include:

- Multi-stage hydraulic lift capability for greater reach

- Enhanced mechanical stability and safety features

- Durable construction for intensive usage

- Suitable for both indoor and outdoor environments

Wondering if a cylinder-cylinder aerial work platform is right for your site? Consider:

- What specific height requirements do you have?

- How much weight will the platform need to support?

- Is mobility or stationary placement more critical for your workflow?

The Guide Rail Elevator

The guide rail elevator is a non-scissor platform lift engineered for the vertical transportation of goods between floors—commonly used in restaurants, manufacturing plants, warehouses, and commercial kitchens. This lift is ideal for locations where excavation for a pit is not feasible, as it offers a minimal platform height of only 5.9 to 11.8 inches (150–300 mm).

The guide rail elevator operates smoothly and is known for its simple, reliable mechanics. Its cost-effective design makes it an economical solution for businesses that need to move goods efficiently between levels. Typical applications include transporting food, supplies, or inventory in multi-story facilities.

Top decision factors for guide rail elevators:

- Ease of installation and integration with existing structures

- Low maintenance and operating costs

- Flexible load capacity and platform size options

- Compliance with local safety and building codes

Curious about guide rail elevator pricing and installation? Contact leading platform lift manufacturers for a customized quote and site assessment.

Self-Propelled Freight Elevator

The self-propelled freight elevator represents the latest in high-altitude operation technology. Powered by rechargeable batteries, these lifts offer full control of walking, steering, and platform elevation from the onboard control panel. Their advanced automation and safety features make them the preferred choice for dynamic, high-efficiency work environments.

Key advantages of self-propelled freight elevators include:

- Ability to move while elevated, increasing productivity

- Integrated pothole protection system for enhanced safety

- Safe ground clearance for indoor and outdoor operations

- Easy maintenance and robust construction

- Environmentally friendly electric power with low noise emissions

Industries that commonly use self-propelled freight elevators include warehousing, logistics, facility management, and large-scale retail operations. These lifts are especially valuable for tasks that require frequent repositioning and quick access to multiple work areas.

Aluminum Alloy Single-Mast Elevator

The aluminum alloy single-mast elevator is a lightweight, portable platform lift designed for single-person operation. Capable of reaching heights of 23 to 26 feet (7 to 8 m) and supporting up to 220 pounds (100 kg), this lift is ideal for indoor maintenance, installation, and inspection activities.

Notable features include:

- Ultra-lightweight aluminum alloy construction for easy maneuverability

- Compact design that fits through standard doorways and into elevators

- Quick setup and breakdown for time-sensitive tasks

- Low energy consumption for cost-effective operation

Considering a single-mast elevator for your facility? Ask about customization options for platform size, safety features, and power supply to best suit your project requirements.

Applications and Benefits of Platform Lifts

Platform lifts are essential tools that deliver unmatched versatility across a spectrum of industries and use cases. Understanding their broad range of applications and the benefits they offer can help buyers and decision-makers select the best lifting solution for their unique needs.

Applications and Uses of Platform Lifts

- Municipal repairs: Facilitating safe access to streetlights, traffic signals, signage, and utility poles.

- Docks: Supporting efficient loading and unloading of cargo, streamlining logistics operations.

- Logistics goods transportation: Moving parcels, pallets, and inventory between warehouse levels with ease.

- Construction: Providing aerial access for building, painting, or inspection tasks on multi-story structures.

- Decoration: Assisting with interior and exterior decorating, including lighting, banners, and seasonal displays.

- Vertical movement between floors: Ensuring accessibility for people with limited mobility and facilitating material flow in multi-level facilities.

- Retail and commercial spaces: Enhancing customer and staff accessibility and safety.

- Healthcare facilities: Assisting with patient transport and equipment movement between floors.

- Public buildings: Improving compliance with ADA (Americans with Disabilities Act) and similar regulations internationally.

Benefits of Platform Lifts

- Cost-effective and durable: Platform lifts are engineered for long service lives and minimal maintenance, offering a high return on investment.

- Lightweight and compact: Many models, particularly hydraulic scissor lifts, are designed for ease of transport and installation in tight spaces.

- High load capacity: Capable of lifting heavy objects and multiple personnel without sacrificing safety or performance.

- Energy-efficient operation: Modern lifts utilize advanced hydraulic or electric systems to minimize energy use and operating costs.

- Enhanced safety: Built-in safety mechanisms, such as emergency stop buttons, guard rails, and overload protection, make platform lifts safer than traditional stairs or ladders, particularly for transporting people.

- Reduced risk of workplace injuries: By providing stable, controlled vertical movement, platform lifts help mitigate the risks associated with manual lifting and working at heights.

- Customizable features: Many platform lifts offer custom platform sizes, finishes, and safety features to meet specific project requirements.

- Improved accessibility: Platform lifts support inclusive environments by ensuring safe vertical mobility for individuals with disabilities or mobility challenges.

Comparing Platform Lifts to Other Lifting Solutions

When researching vertical lifting equipment, buyers often compare platform lifts to traditional elevators, wheelchair lifts, stairlifts, and freight elevators. While each option has its benefits, platform lifts are notable for their versatility, lower installation costs, and adaptability to diverse environments. Whether you need a permanent accessibility solution or a temporary lift for a construction project, platform lifts provide flexible, scalable options.

Need help choosing between a platform lift, stairlift, or freight elevator? Explore our in-depth guides and manufacturer directories to compare specifications, pricing, and installation requirements.

Platform Lift Safety and Regulatory Compliance

Safety is a critical consideration when selecting and using platform lifts. Modern platform lifts are designed to meet or exceed industry safety standards and regulations, such as the ADA (in the United States), CE Marking (in Europe), and national building codes. Key safety features include emergency lowering devices, anti-slip surfaces, safety gates, and overload sensors.

- Always verify that your selected platform lift model is compliant with local and national safety regulations.

- Regular maintenance and inspections are essential for safe operation and to maximize equipment lifespan.

- Operator training should be provided to ensure safe, efficient use of any platform lift.

How to Choose the Right Platform Lift for Your Application

Finding the best platform lift for your needs involves careful consideration of several factors. Here are some key questions to guide your search:

- What is the maximum height you need to reach?

- What are your load capacity requirements?

- Will the lift be used primarily indoors, outdoors, or in both settings?

- How much space is available for installation and operation?

- Do you need a stationary or mobile lift solution?

- Are there specific safety or accessibility standards your lift must meet?

- What is your budget for initial purchase, installation, and ongoing maintenance?

- Do you require custom features such as folding platforms, remote controls, or weatherproofing?

Still have questions? Contact a platform lift specialist to discuss your requirements and receive personalized recommendations.

Choosing the Right Platform Lift Manufacturer

To ensure the most successful outcome when purchasing a platform lift, it’s essential to partner with a reputable platform lift manufacturer. Our comprehensive platform lift manufacturers directory lets you compare leading suppliers, evaluate their experience, and request quotes for your specific project.

Each platform lift manufacturer has a dedicated business profile page showcasing their capabilities, certifications, and unique value propositions. You can easily connect with suppliers via a built-in contact form for more information or to request a quote. Use our patented website previewer to quickly assess each company’s specialization, product range, and customer service approach. For efficiency, our RFQ (Request for Quote) system allows you to contact multiple platform lift companies simultaneously using a single submission.

- Compare manufacturer credentials, including ISO certifications, safety records, and years in business.

- Review case studies and testimonials to gauge customer satisfaction and project success rates.

- Request detailed product catalogs, technical specifications, and sample pricing to inform your decision-making.

Ready to Find the Best Platform Lift for Your Needs?

Start your search by browsing our platform lift manufacturers directory. If you have unique requirements or need assistance comparing products, reach out to our experts for tailored recommendations. Whether you require a hydraulic scissor lift, guide rail elevator, self-propelled freight elevator, or custom platform lift solution, our network of trusted manufacturers can deliver solutions that align with your operational goals and budget.

Frequently Asked Questions about Platform Lifts

- What are the main differences between platform lifts and traditional elevators?

Platform lifts are generally more compact, cost-effective, and easier to install than standard elevators. They are ideal for locations where space, budget, or structural constraints make traditional elevators impractical. - How much weight can a typical platform lift support?

Load capacities vary widely depending on the lift type and manufacturer, with most commercial models supporting between 500 lbs and several tons. - Are platform lifts suitable for outdoor use?

Many platform lifts are designed for both indoor and outdoor applications, with weatherproof features and corrosion-resistant materials available for harsh environments. - Do platform lifts require special maintenance?

Routine maintenance is required to ensure safety and performance. Most manufacturers offer service plans and provide detailed maintenance schedules for their equipment. - Can platform lifts be customized?

Yes, manufacturers offer a range of customization options including platform size, lifting height, access controls, finishes, and safety features.

Interested in learning more about platform lifts for your application? Contact our team to discuss your project, request product literature, or schedule a consultation with an experienced platform lift provider.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services