Hydraulic lift systems are tools powered by hydraulics, or liquid mechanics, to raise and lower, support and lift and move objects that could not be transported using manual labor alone. Read More…

Our hydraulic lifts are manufactured using a combination of innovation, state of the art technology, the latest engineering designs, and the highest quality products.

Advance Lifts designs & manufactures hydraulic lifts and other models of material handling equipment. Our ultra high-cycle lifts have a 3,000,000 cycle warranty & our patented platform centering devices reduce lift wear from off centered loading.

We manufacture hydraulic lifts and a whole lot more. Our goal is to be the best in both quality and customer service. In fact, our mission statement stays we will work hard so you can live easier.

Our hydraulic lifts are a testament to our unwavering commitment to quality and durability. Crafted with exceptional engineering, each product showcases innovative ideas that push the boundaries of what material handling equipment can achieve. We take pride in the heavy-duty materials we utilize, ensuring that our hydraulic lifts meet and exceed the demands of diverse industries.

We have a wide line of vertical lifts, but customize each product for our customers’ specific applications. Vertical Reciprocating Conveyors--VRCs are for material handling only and can not be used to transport people.

At Metro Hydraulic Jack, we have been distributing pneumatic, hydraulic and mechanical equipment and tools since 1941. Our product lines include automotive lubrication systems, hydraulic tools for construction, hydraulic lifts and similar types of material handling equipment, mobile hydraulic motors and railroad lifting equipment. We also service most lines of equipment.

Isotech is a distributor of hydraulic lifts and telescopic lifting columns for medical, radiological, and industrial applications. Our columns provide a stable, reliable, and maintenance free guiding system without any play. We can customize the load, speed, and travel to meet your individual application requirements.

More Hydraulic Lift Manufacturers

Hydraulic Lift Applications

Hydraulic lifts find their primary roles in a multitude of sectors including manufacturing, construction (particularly in roofing and masonry), automotive, and aviation industries. Additionally, they serve essential functions in general transportation, shipping, and docking operations. In these industries, hydraulic lift tables serve various purposes: from loading and unloading goods, repositioning warehouse materials for easier access, elevating workers to unreachable heights, to assisting in maintenance and material handling tasks.

Warehouses extensively utilize scissor lifts for personnel elevation and pallet lifts for efficient material movement. Additionally, in aviation, hydraulic lifts function as passenger and luggage elevators. Moreover, hydraulic lifts find applications in residential and assisted living settings to enhance accessibility for individuals with disabilities.

History of Hydraulic Lifts

Since ancient times, lift tables and platforms have accompanied humanity’s pursuit of towering architecture. In Roman times, for instance, they ingeniously hoisted building materials via platforms operated by slaves pulling ropes.

Joseph Bramah’s pioneering hydraulic equipment, notably the hydraulic press, revolutionized both agriculture and industry following its patent in England. This invention spurred the adoption of hydraulic power for diverse applications, from cranes and elevators to trains and rotating bridges. Sir William Armstrong later innovated the hydraulic crane in 1846, marking another milestone. During the Industrial Revolution, engineers further refined hydraulic technology, culminating in the introduction of modern hydraulic elevator lifts in New York City in 1870. Prior to this advancement, elevators relied on steam engines fueled by coal for operation.

In 1925, Peter Lunati, an American auto mechanic, revolutionized automotive maintenance by patenting the first fully hydraulic automotive lift. Inspired by the hydraulic chair in his barber shop, which raised and lowered effortlessly, Lunati envisioned applying this mechanism to car lifts. His innovation eliminated the need to labor on the ground during repairs. Within two decades, the widespread adoption of automotive lifts prompted American manufacturers to establish the Automotive Lift Institute (ALI) to standardize safety and performance across the industry.

In 1963, Charles L. Larson revolutionized hydraulic lifting with his invention of the scissor lift. Around the same time, Kaspar Klaus introduced another breakthrough, the sidelifter. By the 1980s, engineers further advanced the technology with the hydraulic scissor car lift. Continuing into the 21st century, manufacturers began offering four-post hydraulic vehicle platform lifts starting in 2000. The modern hydraulic lift industry persists in innovating to enhance organization and accessibility, rooted in time-tested designs like the hydraulic elevator. Moreover, contemporary emphasis is heavily placed on ergonomics, ensuring optimal usability and comfort.

How Hydraulic Lifts Work

In all its variations, whether in function, design, or size, every hydraulic lift operates on the same principle. At its core, a hydraulic lift harnesses the force through a hydraulic cylinder, which derives its power from pressurized hydraulic fluid, typically oil. Within the cylinder, a piston rod propels the hydraulic fluid, facilitating the transfer of energy between different points. This mechanism effectively multiplies the force applied, enhancing the lifting capacity significantly.

A hydraulic lift operates by utilizing pressure exerted on an incompressible liquid within a cylinder to move a piston upward. When incompressible oil is pumped into the cylinder, it pushes the piston to its upper position. To lower the piston, a valve opens, allowing the oil to release under the influence of gravitational force.

The mechanism operates by exerting force at a specific location on an incompressible liquid, transmitting this force to another location. It employs two pistons interconnected via an oil-filled pipe. As the handle compresses the incompressible oil, it moves from the reservoir into the high-pressure chamber. This pressurized oil then drives the ram upwards.

Force Generated

In a hydraulic system, the force produced hinges on the dimensions of the pistons. For instance, if one piston measures 2 inches and another measures 6 inches—three times larger—the force generated scales exponentially. A modest 100-pound force exerted by the smaller piston could magnify to an impressive 900 pounds when applied to the larger piston.

Parts of a Hydraulic Mechanism

Hydraulic systems serve diverse purposes, yet their fundamental operational principles and componentry remain consistent across all applications.

At the heart of every hydraulic system lies its vital fluid or liquid component. The laws of physics decree that the fluid pressure remains constant as it transmits through the hydraulic system. Below is an overview of every part of a hydraulic mechanism:

- Hydraulic Fluids

- Hydraulic Valves

- Hydraulic Circuits

- Hydraulic Motor

- Hydraulic Pump

- Hydraulic Cylinder

- Hydraulic Pistons

Hydraulic Fluids

Hydraulic fluids play a crucial role in transmitting power and enabling machinery movement within hydraulic systems. They encompass diverse types tailored for specific applications. Environmentally conscious water-based fluids, while eco-friendly, are constrained by their reduced lubricating capabilities. In contrast, prevalent oil-based variants such as mineral and synthetic oils deliver robust lubrication and stability, making them widely preferred in industrial settings. When it comes to hydraulic fluids, each type serves distinct purposes. Glycol ethers excel in lubrication and thermal durability. Organophosphate esters boast fire resistance, crucial for high-risk fire scenarios. Polyalphaolefin (PAO) fluids offer stability against oxidation and heat. Antifreeze fluids prevent freezing in cold climates, while silicone oil-based fluids thrive in high-temperature environments. To select the right fluid, consider factors such as temperature range, pressure requirements, environmental impact, and compatibility with the equipment. For hydraulic lifts, commonly chosen options include oil-based and synthetic fluids like PAO, favored for their lubricating qualities and compatibility with lift components. Consulting manufacturers’ recommendations is essential for ensuring the optimal hydraulic fluid choice.

Hydraulic Valves

In hydraulic systems, hydraulic valves serve as indispensable components responsible for regulating the flow, pressure, and direction of hydraulic fluid. These valves are crucial for managing hydraulic actuators like cylinders in hydraulic lifts. They exist in various types, including directional control valves, pressure control valves, flow control valves, and check valves, each tailored to specific functions.

Of particular significance in hydraulic lifts are directional control valves. These valves dictate the path of hydraulic fluid, directly influencing the lift platform’s motion. By selectively opening and closing ports, directional control valves control whether hydraulic fluid extends or retracts cylinders, thereby raising or lowering the lift platform.

Pressure control valves in hydraulic lifts serve to uphold optimal system pressure, preventing overload of hydraulic components and ensuring secure lifting operations. Meanwhile, flow control valves regulate the speed of hydraulic actuators, enabling precise and smooth movements for lifting and lowering operations.

When a hydraulic lift is in operation, its hydraulic valves respond to commands from the operator, usually via electrical switches or manual controls. Activation of the lift’s control system triggers specific hydraulic valves, guiding pressurized fluid to the cylinders. This action sets the platform in motion, initiating its movement.

Hydraulic valves form the bedrock of hydraulic lifts, crucial for their smooth operation and safety. They meticulously govern the flow and pressure of hydraulic fluid, guaranteeing precise and efficient lifting maneuvers. By directing and managing the fluid, these valves play an indispensable role in maintaining the controlled and dependable movement of heavy loads, ensuring accuracy and reliability in hydraulic lift systems.

Hydraulic Circuits

The hydraulic circuit in a hydraulic lift operates akin to a symphony conductor, orchestrating the efficient and secure lifting and lowering of heavy loads. When the lift’s control system initiates, the pump springs into action, pressurizing hydraulic fluid housed in the reservoir. This pressured fluid courses through meticulous control valves, dictating both its flow and path to the hydraulic cylinders. These cylinders, synchronized with the lift platform, extend or retract in response to the fluid’s directed movement, effortlessly raising or lowering the load.

The control valves are pivotal in the lift’s functionality, as they govern the flow of hydraulic fluid to the cylinders, thereby regulating both the speed and direction of the lift. Through meticulous adjustment of these valve openings, operators can attain exacting command over the ascent and descent, guaranteeing seamless and steadfast operations.

Furthermore, hydraulic circuits in lifts commonly incorporate safety mechanisms, such as pressure relief valves. These safeguards are designed to avert overloading or the accumulation of excessive pressure, ensuring the safety of both the lift and its operators by mitigating potential damage or accidents.

The hydraulic circuit within a hydraulic lift stands as the vital mechanism converting the energy of pressurized hydraulic fluid into mechanical force. This transformation enables the lift to adeptly elevate and lower heavy loads with meticulousness, effectiveness, and utmost safety.

Hydraulic Motor

A hydraulic motor functions as a mechanical wizardry that transforms the force of hydraulic pressure and fluid flow into the enchanting dance of rotational mechanical power. Similar to hydraulic cylinders, which move in straight lines, this marvel conjures rotary motion. Its mystical components include a spinning shaft nestled within a housing, complemented by an array of gears, pistons, or vanes hidden within. When the elixir of hydraulic fluid is channeled into its core, these internal magics stir into motion, invoking mechanical might at the motor’s very heart.

In a hydraulic lift, the hydraulic motor serves as the powerhouse, generating rotational force essential for operating the lifting mechanism. It interfaces directly with the lift’s drive system, often via gears or a gearbox, to translate its rotational power into vertical motion. This transformation enables the lift to smoothly elevate and descend the platform as needed.

When the lift operator triggers the hydraulic lift, the hydraulic pump energizes the hydraulic fluid, channeling it towards the hydraulic motor. Upon receiving the pressurized fluid, the motor springs to life, converting this energy into mechanical power that propels the lift’s drive system. This system, in a synchronized dance, converts the rotational force from the hydraulic motor into linear motion, gracefully guiding the lift platform either upwards or downwards.

The hydraulic motor’s capacity to produce substantial torque and rotational force guarantees adept handling of heavy loads and efficient movement for the lift. Its adjustable speed and directional control render it ideal for precisely positioning the lift platform. Furthermore, hydraulic motors are celebrated for their robustness and capability to endure high-pressure environments, cementing their reliability as integral components within hydraulic lift systems.

The hydraulic motor acts as the vital intermediary between the hydraulic pressure created by the pump and the mechanical force necessary for raising and lowering the platform in a hydraulic lift. By transforming hydraulic power into rotational force, the hydraulic motor empowers the lift to perform its elevation task efficiently and securely.

Hydraulic Pump

In the world of hydraulics, a hydraulic pump stands as the powerhouse, transforming mechanical muscle into hydraulic might. Its mission: to generate pressure that fuels hydraulic systems, driving fluid through circuits with the force needed to operate machinery. With each cycle, it channels hydraulic fluid from inlet to outlet, crafting a stream of pressurized liquid that breathes life into hydraulic motors and other vital components.

In the realm of hydraulic motors, the hydraulic pump stands tall as the chief powerhouse. Once the hydraulic system springs to life, the pump eagerly inhales hydraulic fluid from the reservoir through its inlet. Inside the pump, whether gears are whirling, pistons are pumping, or vanes are sweeping, these internal movers displace the fluid, creating a surge of pressure. This pressurized hydraulic fluid, now brimming with energy, courses towards the hydraulic motor. Here, it ignites the motor’s internal mechanisms, setting in motion a graceful dance of rotation.

The speed and torque of the hydraulic motor hinge decisively upon the output flow rate and pressure of its hydraulic pump. Elevated flow rates and pressures amplify the rotational speed and torque exerted at the motor’s output shaft. It is imperative for the pump to deliver adequate fluid at optimal pressure to ensure the motor operates smoothly and efficiently.

Various hydraulic pumps populate the mechanical landscape—gear pumps, vane pumps, and piston pumps—each tailored for particular applications. While their designs differ, they share a singular mission: to supply the hydraulic energy that powers the hydraulic motor, transforming it into the rotational force that drives machinery.

The hydraulic pump stands as the heartbeat of a hydraulic system, transforming mechanical power into the lifeblood of hydraulic energy. It serves as the primary source of pressurized hydraulic fluid, vital for powering a hydraulic motor. This pressurization sets the stage for rotational motion, essential for activating hydraulic lifts and machines, ensuring they operate smoothly and fulfill their designated roles.

Hydraulic Cylinder

Hydraulic cylinders are the muscle of hydraulic systems, transforming hydraulic pressure into the linear force and motion needed for mechanical tasks. These devices consist of a cylindrical barrel housing a piston, which is connected to a rod that projects from one end of the cylinder. As hydraulic pressure is exerted on the piston, it travels the cylinder’s length, driving the rod to either extend or retract, akin to a limb in motion.

In a hydraulic system, the hydraulic cylinders act as crucial connectors, converting the rotational force from the motor into linear thrust. This transformation enables hydraulic lifts and other machinery to execute precise movements. These cylinders are typically linked to the load or the mechanical element requiring direct, linear displacement.

As the hydraulic motor spins into action, it channels its rotational force to the hydraulic cylinder. Inside this cylinder, a rush of pressurized fluid bears down on the piston, prompting it to glide smoothly along the cylinder’s axis. With every surge of fluid, the attached rod either stretches out or pulls back, determined by the flow’s course. This orchestrated movement of the piston translates into the linear dance that can elevate a hydraulic lift platform, shift mechanical parts, or execute a multitude of tasks demanding a straight-line push.

Hydraulic cylinders come in a wide array of sizes and designs, making them adaptable to unique needs. Their prowess in exerting significant linear force renders them perfect for demanding operations like hoisting hefty weights in hydraulic elevators or steering mechanisms in construction and industrial equipment.

Hydraulic cylinders act as the mighty muscles of hydraulic systems, transforming hydraulic pressure into linear force and movement. Within the realm of a hydraulic motor, these cylinders serve a critical function, converting the motor’s spinning action into straightforward motion. This essential transformation allows hydraulic lifts and machines to perform tasks with precision and efficiency.

Hydraulic Pistons

Hydraulic pistons, the vital heartbeats of hydraulic cylinders, harness the power of hydraulic pressure to generate linear mechanical force and motion. Shaped like sturdy cylinders, these pistons nestle perfectly within the cylinder’s barrel. As hydraulic pressure is introduced, the piston embarks on a journey along the cylinder’s length, masterfully extending or retracting the rod to which it’s connected.

In a hydraulic lift, the pistons inside the hydraulic cylinders are crucial for moving the lift platform up and down. When the lift is turned on, the hydraulic pump pressurizes the fluid, sending it into the cylinders. This pressurized fluid moves the pistons along the length of the cylinders. As the pistons move, they drive the rods connected to them, which in turn are attached to the lift platform. The movement of these rods causes the platform to move vertically, lifting or lowering it as needed.

Hydraulic pistons, acting as robust alchemists, transform hydraulic pressure into precise linear motion, empowering hydraulic lifts to manage substantial loads with both ease and precision. By meticulously regulating the hydraulic fluid’s flow to these pistons, operators of lifts can orchestrate smooth, controlled ascents and descents, thus ensuring lifting operations that are not only safe but also efficient. Engineered to endure the rigors of high pressure, these pistons deliver steadfast performance, cementing their vital role in the mechanics of hydraulic lifts across diverse sectors like construction, manufacturing, and material handling.

Hydraulic pistons, the powerhouse elements of hydraulic cylinders, transform hydraulic pressure into the linear dance of mechanical force and motion. Within the realm of hydraulic lifts, these pistons orchestrate the ascent and descent of platforms through the eloquent extension and retraction of their connected rods. Engineered for durability and capable of bearing significant burdens, hydraulic pistons are indispensable for ensuring the safe and efficient functioning of hydraulic lifts across various applications.

Types of Hydraulic Lifts

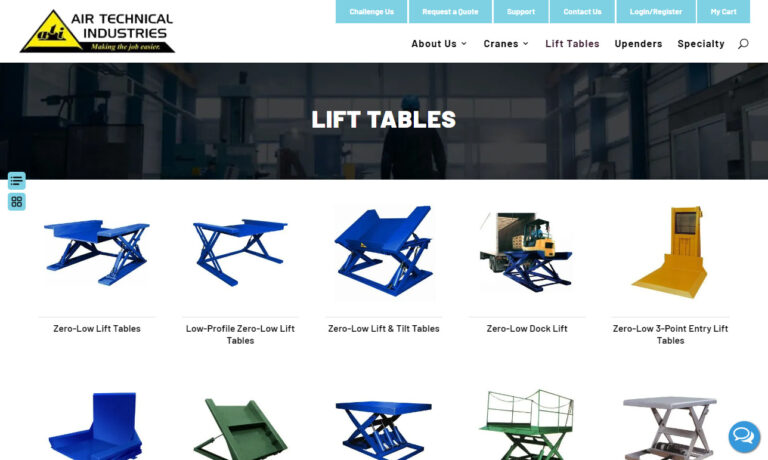

Hydraulic lifts come in various forms, including scissor lifts, aerial lifts, and mobile scissor lifts. Other types include platform lifts, pallet lifts, vehicle lifts, and post car lifts, each designed to meet specific lifting needs.

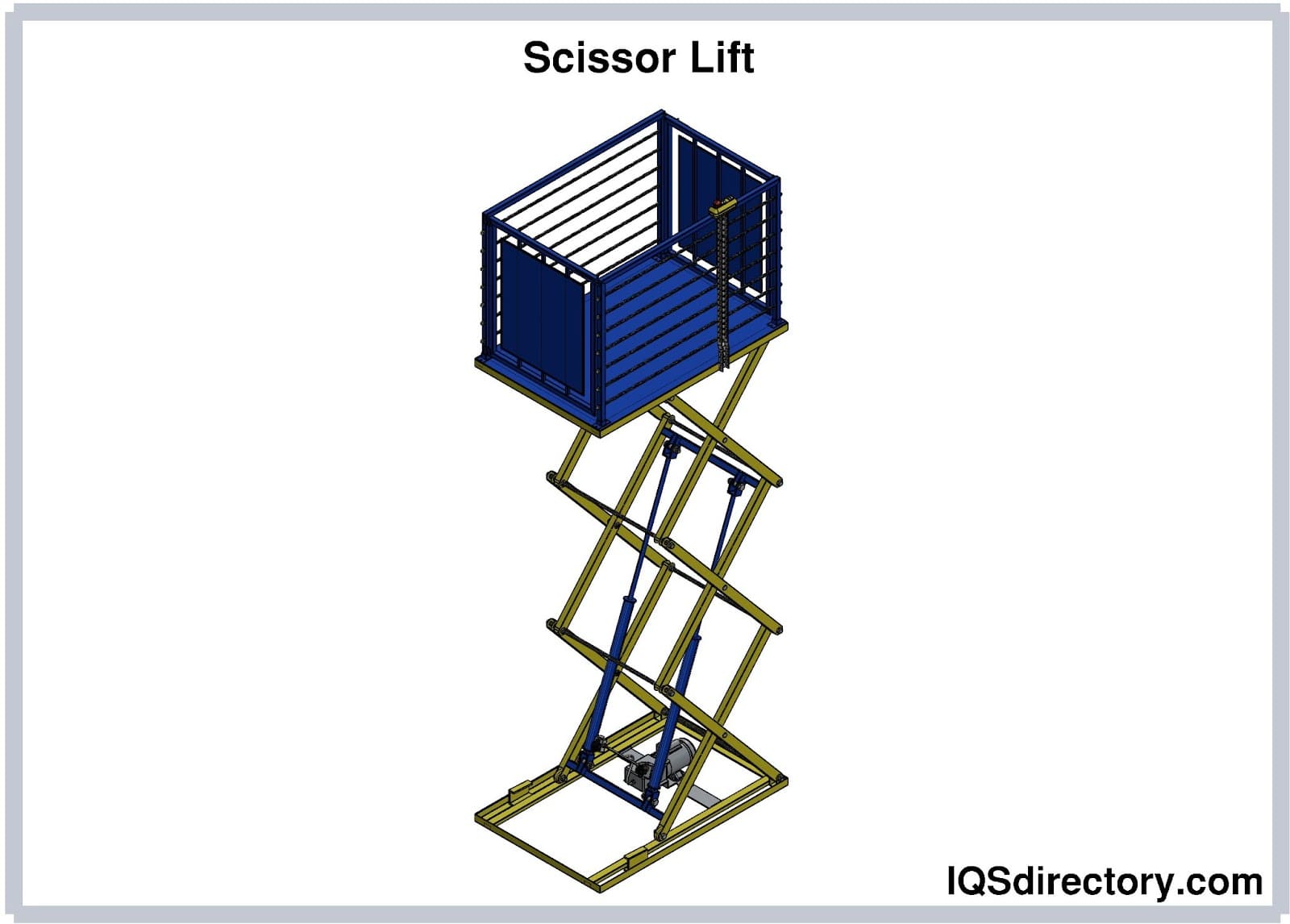

Hydraulic Scissor Lift

Scissor lifts, often the go-to choice for hydraulic lifts, operate through a unique, accordion-like mechanism at their base. Powered by hydraulic cylinders and an electric pump, these lifts smoothly ascend as their crisscrossed base stretches out. This design allows the platform above to reach various heights, making them perfect for handling substantial, bulky loads across expansive workspaces. Commonly seen on construction sites, in building maintenance tasks, and during the rigging and setting up of lights and equipment in studios and theaters, scissor lifts are a staple in industries requiring vertical mobility.

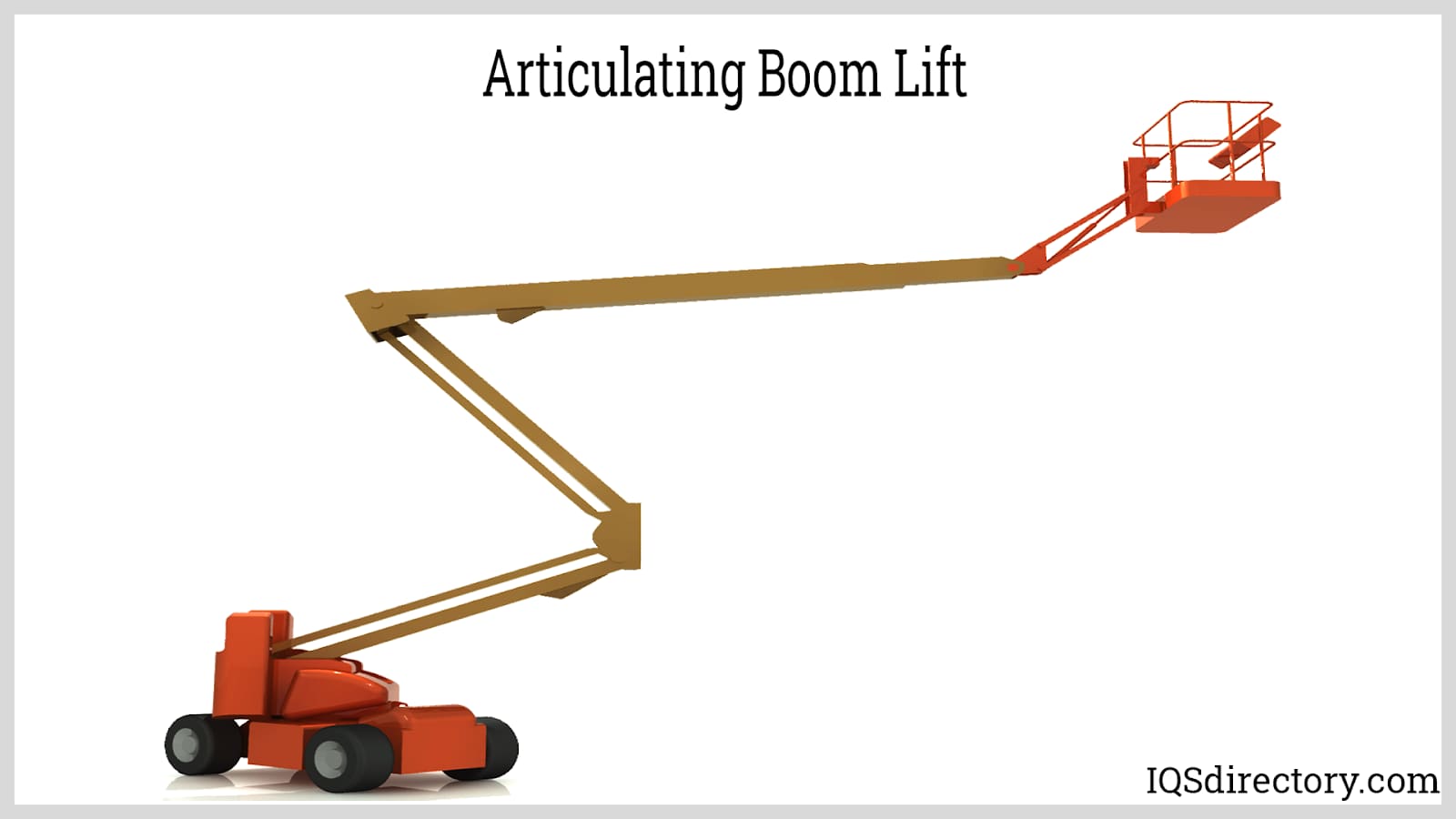

Aerial Lift

Aerial lifts, often referred to as aerial work platforms, fall under the broader category of scissor lifts. These devices can soar between ten to fifty feet high, making them ideal for reaching the upper echelons of shelving in warehouses.

Mobile Scissor Lift Table

Mobile scissor lift tables glide on casters, offering a blend of mobility and utility. These versatile units often come equipped with tiltable surfaces and foot-operated pumps, enhancing their ability to securely move bulky or unwieldy objects. Commonly spotted on construction sites and in the backstage areas of entertainment venues, these tables are essential for dynamic environments where adaptability is key.

Platform Lift

Platform lifts, often referred to as elevated work platforms, bear a resemblance to their smaller counterparts, hydraulic lift tables, but on a grander scale. Due to their expansive dimensions, these lifts are typically employed for heavy-duty lifting operations.

Pallet Lift

Pallet lifts, commonly referred to as transporters, elevate pallets from the ground to an elevated position. To enhance safety during operation, pallets often feature designated spaces that accommodate the pallet lift. These devices are ideally suited for shipping and material handling applications.

Vehicle Lift

Vehicle lifts, often referred to as automotive or truck lifts, serve a straightforward purpose: hoisting vehicles in inspection bays and repair shops. These robust titans of the hydraulic lift world boast formidable strength, enabling them not just to elevate cars and trucks, but also to handle heavier giants like school buses, dump trucks, and other oversized vehicles.

Post Car Lift

A post car lift is a specialized version of the typical vehicle lift. Typically, it includes four arms linked to a carriage system, two hydraulic cylinders, a hydraulic power unit, and a pair of vertical support columns, all complemented by an assortment of accessories such as cables, hoses, and pulleys. These lifts are generally fixed in place and anchored securely to a concrete floor.

Hydraulic Lift Table Components

A hydraulic lift table consists of various components working together to provide efficient lifting and lowering of heavy loads. These components include hydraulic fluid (also known as hydraulic oil), hydraulic valves, a hydraulic roller (for opening and closing valves), a hydraulic pump, hydraulic cylinders, a rotary joint, a drive machine, and a land surface. We discuss each of these components, and their specific function in a hydraulic lift table, in greater detail below.

Hydraulic Fluid (Hydraulic Oil)

Hydraulic fluid serves as the lifeblood of a hydraulic system, channeling power throughout. Energized by the hydraulic pump, this fluid surges into the hydraulic cylinders, where it generates the necessary force to elevate platforms. Beyond its primary role in power transmission, this fluid also doubles as a coolant and lubricant, safeguarding the system’s moving components.

Hydraulic Valves

Hydraulic valves control the flow of fluid in a hydraulic lift table, precisely managing how the hydraulic fluid moves. These include directional control valves and pressure control valves, which regulate the movement and speed of the fluid to the hydraulic cylinders. This allows for precise control of the lift’s motion and speed.

Hydraulic Roller (for Opening and Closing Valves)

The hydraulic roller, alternatively called a hydraulic pilot-operated valve or control valve, serves to manage the operation of other hydraulic valves. It employs a lesser hydraulic force to govern the flow of more substantial hydraulic forces, ensuring efficient and precise control of valve mechanisms.

Hydraulic Pump

The hydraulic pump serves as the heart of the hydraulic lift table, transforming mechanical power into hydraulic energy. By pressurizing the hydraulic fluid, it creates the vital flow that powers the lift’s hydraulic cylinders, enabling smooth and efficient operation.

Hydraulic Cylinders

Hydraulic cylinders serve as the powerful arms that convert the pressure of hydraulic fluid into the straight-line muscle needed to move machinery. Depending on which way the fluid flows, they either stretch out or pull back, enabling them to raise or drop the lift platform with a smooth, controlled motion.

Rotary Joint

The rotary joint serves as a dynamic conduit, channeling hydraulic fluid from a static origin, like the pump, to the agile elements, such as the hydraulic cylinders. This design prevents leaks and maintains an unbroken stream of fluid, ensuring seamless operation as the platform articulates.

Drive Machine

The drive machine serves as the heart of the system, powering rotational movement that the hydraulic cylinders then transform into linear motion, allowing the platform to ascend or descend gracefully.

Land Surface

The ground serves as a solid foundation for the hydraulic lift table, anchoring the entire structure securely in place.

In an operational hydraulic lift table, the hydraulic pump pressurizes the fluid, channeling it through valves and rollers to manage the flow and direction. This controlled fluid reaches the hydraulic cylinders, prompting them to extend or retract, thereby raising or lowering the platform. The rotary joint maintains a continuous fluid supply throughout the platform’s movement. The drive mechanism spins into action, converting rotational movement into the straight-line motion of hydraulic cylinders that raise or lower the platform. The seamless and accurate performance of the hydraulic lift table hinges on the flawless collaboration and function of these integral parts.

How to Use Hydraulic Lifts

We can’t tell you how to use every single hydraulic lift out there, because every individual machine is different, but we can offer you the following general advice:

- Before powering up, ensure all is set for a safe start. For instance, if your lift is equipped with casters, verify they’re securely locked to prevent any unexpected movements. Next, take a moment to survey your surroundings: familiarize yourself with the locations of all objects and people nearby, and notify your coworkers that the lift will be in use. This precaution helps avoid surprises for you and others once the machinery springs to life.

- Next, activate the lift. This could involve flipping a switch or manipulating a control lever, depending on your model. If your lift is on wheels, unlock the casters and glide the lift to the desired position. Once it’s positioned, lock the casters back in place. Additionally, if your lift is equipped with safety bars, raise them now. Once everything is securely set, you can start operating the controls to elevate your load.

Another key aspect of operating hydraulic systems safely is handling the equipment with care. This means respecting its limits and not overburdening it with weights beyond its capacity. Exceeding the designated load not only risks damaging vital parts, like the hydraulic fluid and cylinders, but also increases the likelihood of an immediate breakdown. Such a failure endangers not just the machine, but also the safety of anyone and anything in its vicinity.

Benefits of Hydraulic Lifts

Hydraulic lifts are a powerhouse of utility. Engaging with these mechanical marvels unveils a host of advantages: durability, operational efficiency, and economic value. Their adaptability shines through in various applications, from elevating passengers to hoisting supplies. Moreover, hydraulic lifts dramatically enhance safety and reduce mishaps, diminishing both the frequency and the financial drain of workplace incidents. This boost in safety not only streamlines processes but also amplifies the profitability of your production investments.

Hydraulic Lift Design and Customization

When crafting a hydraulic lift, manufacturers meticulously consider various design elements such as the choice of material, mobility features, automation level, durability, load capacity, and height constraints.

The nature of hydraulic lifts, which operate under significant pressure, dictates the necessity for materials that can withstand intense stress. Options typically include stainless steel, woven wire, and rubber. For the toughest tasks or where maximum durability is essential, stainless steel is the material of choice. Mobility is engineered into some lifts through the integration of wheels, making them portable, while others are fixed installations, integral to production lines. Depending on the intended use, these lifts may range from fully manual to partially or fully automated systems.

Manufacturers have the flexibility to tailor the aforementioned features to suit specialized applications. Moreover, they can introduce personalized touches such as custom colors and finishes, along with additional elements like warning lights, supplementary arms, protective skirting, and foot-operated controls.

Uses of Stainless Steel Lifts

In the meticulous realms of food and pharmaceutical production, as well as certain chemical manufacturing zones, rigorous sanitation practices are paramount. These industries champion pristine environments to fend off any contaminants that might tarnish product quality. Here, equipment forged from stainless steel plays a pivotal role due to its compliance with the exacting standards mandated by industry regulators. The impenetrable surface of stainless steel acts as a formidable shield against a multitude of impurities, safeguarding the integrity of the products it encases or manipulates. Moreover, its resistance to corrosion and ability to endure regular, intensive cleanings make it an indispensable ally in maintaining the sanctity of these critical manufacturing processes.

Several uses of stainless steel lifts are as follows:

In the intricate dance of manufacturing, the chore of systematically feeding ingredients into various machines emerges as both laborious and critical, particularly when the stage is set for large-scale production. Employing stainless steel lifts to introduce ingredients into the process not only streamlines the workflow but also enhances safety. These production tasks, often monotonous and physically taxing, find relief in the ergonomic embrace of stainless steel lifts. Designed to meld effortlessly with existing systems, these lifts not only accelerate efficiency but also curtail the likelihood of workers suffering from musculoskeletal injuries.

Stainless steel portable tippers and dumpers are employed to securely shift bulk materials between containers. These essential tools often handle stainless steel or plastic drums, which serve as storage vessels for bulk materials in sectors like food processing and pharmaceutical manufacturing. They manage vast amounts of raw materials, intermediate products, finished goods, and waste destined for disposal. Manually tilting these drums to pour their contents into a receiving container is a physically taxing task that, if done carelessly, can lead to injuries.

Stainless steel lifts serve as versatile tools for transporting materials from one location to another. Equipped with wheels for added mobility, these lifts facilitate smooth transfers during loading and unloading by adjusting to the desired height with ease.

Stainless steel man lifts are ideal for accessing hard-to-reach locations. These stationary platforms can elevate up to 216 inches, offering a safe and stable surface for workers thanks to their abrasive finish. Their compact design also allows for easy maneuvering in tight spaces.

Stainless steel lifts, designed as pallet inverters, are readily available for efficient pallet exchange. These devices simplify the process, allowing pallets to be quickly and easily swapped out. They can be tilted or fully inverted, facilitating the smooth transfer of the pallet’s contents. With pallet inverters, accessing the bottom of a load is effortless, eliminating the need for manual unloading. Additionally, they help prevent the settling of solids in liquid containers with suspended particles. By inverting the pallet, the container’s contents are automatically agitated.

Stainless steel lifts, also functioning as stackers, are ideal for elevating and transporting hefty loads to high shelves. Their compact design allows them to maneuver through narrow aisles effortlessly. These lifts ensure the smooth stacking of goods, preventing any damage during the loading and unloading process.

Hydraulic Lift Safety and Compliance Standards

When purchasing a hydraulic lift, ensuring it meets all relevant safety and compliance standards is crucial. Different industries and regions have varying requirements, but some standards are widely recognized. OSHA standards in the United States prioritize worker safety. In the European Union, EN standards focus on equipment safety, while BS EN standards are adaptations of these for the United Kingdom. Globally, many industries follow ISO standards, which set international benchmarks for safety and quality. This list is not exhaustive, so it’s essential to consult with your supplier and industry experts to fully understand all the applicable standards for your hydraulic lift.

Safety Tips

- Follow the manufacturer’s guidelines for safe usage.

- Ensure the lift is labeled with the manufacturer’s name and installation date.

- Keep a detailed and up-to-date repair log.

- Stand to the side while the lift is in operation.

- Properly position the load on the lift and avoid exceeding its weight capacity.

- Keep the lift clear of overhead and ground-level obstacles.

- Maintain a clean, oil-free floor under the lift to prevent slipping hazards.

- Steer clear of holes, ditches, slopes, or uneven terrain.

- Maintain a minimum distance of 10 feet from electrical lines and power sources.

- Regularly check the oil levels on hydraulic lifts.

- Remove lifts from service immediately if any malfunction is detected.

Finding the Right Hydraulic Lift Supplier

For the best results when purchasing a hydraulic lift, it’s crucial to compare several suppliers using our comprehensive directory. Each supplier has a detailed business profile showcasing their expertise and capabilities, complete with a contact form for direct inquiries or quote requests. Utilize our unique website previewer to swiftly understand each company’s specialties. Finally, streamline your communication by using our straightforward RFQ form to contact multiple hydraulic lift suppliers simultaneously.

Check out our Crane Manufacturers website

Check out our Wire Rope website

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services