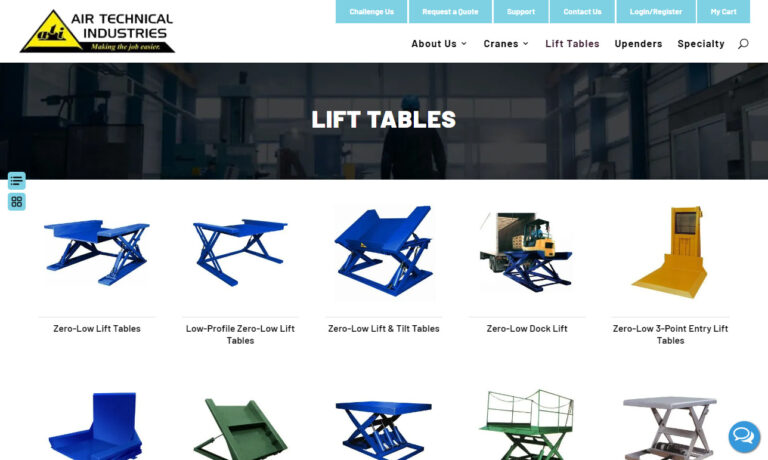

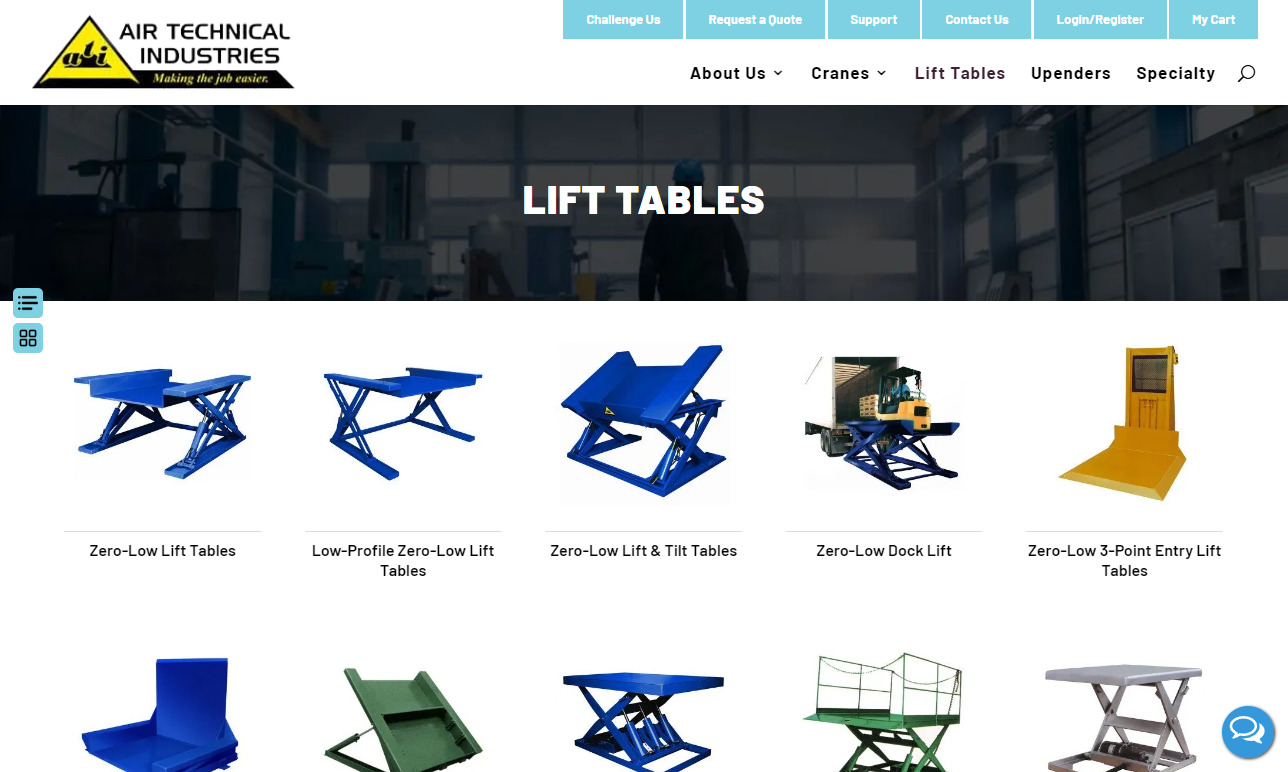

There are many forms of table lifts, which vary by capacity, structure, design, and workload. The varieties and types are endless, beginning with ones that are built to hold lightweight boxes when unloading a truck, to ones that can lift a diesel engine. Read More…

Our hydraulic lifts are manufactured using a combination of innovation, state of the art technology, the latest engineering designs, and the highest quality products.

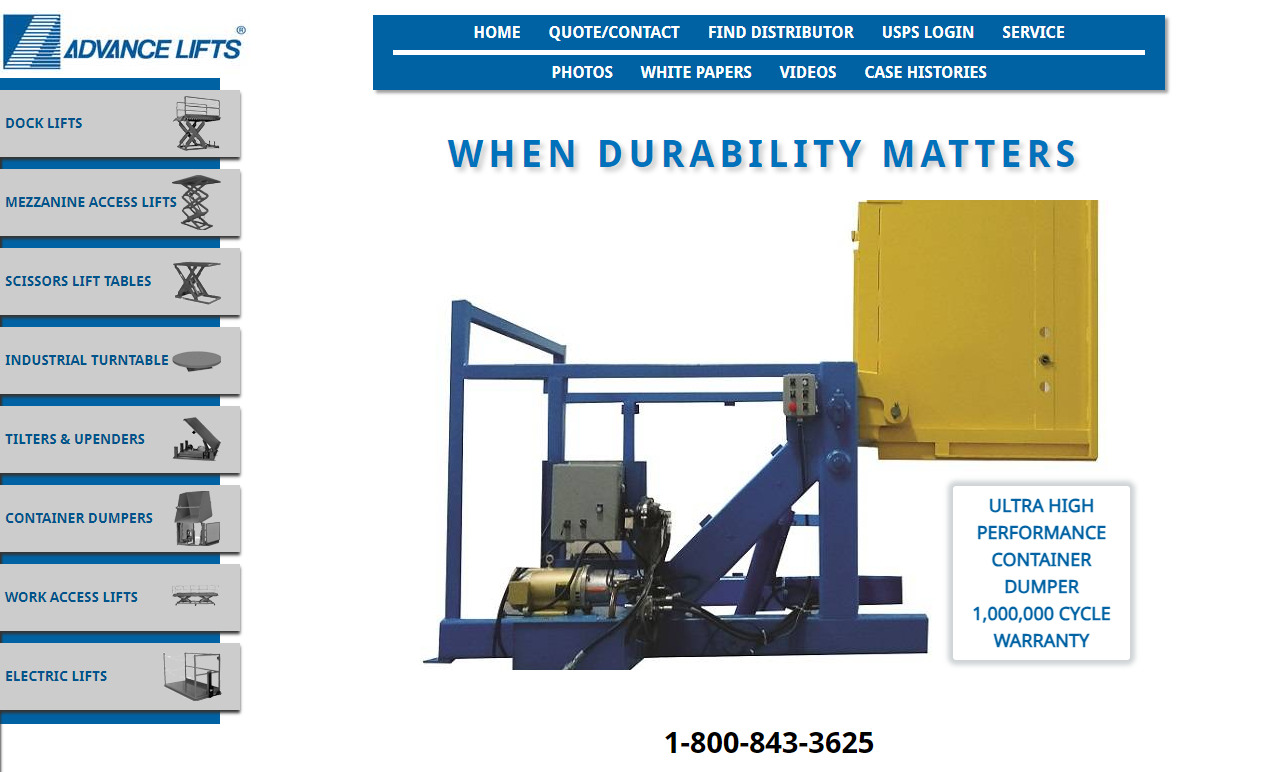

Advance Lifts designs & manufactures hydraulic lifts and other models of material handling equipment. Our ultra high-cycle lifts have a 3,000,000 cycle warranty & our patented platform centering devices reduce lift wear from off centered loading.

We manufacture hydraulic lifts and a whole lot more. Our goal is to be the best in both quality and customer service. In fact, our mission statement stays we will work hard so you can live easier.

Our hydraulic lifts are a testament to our unwavering commitment to quality and durability. Crafted with exceptional engineering, each product showcases innovative ideas that push the boundaries of what material handling equipment can achieve. We take pride in the heavy-duty materials we utilize, ensuring that our hydraulic lifts meet and exceed the demands of diverse industries.

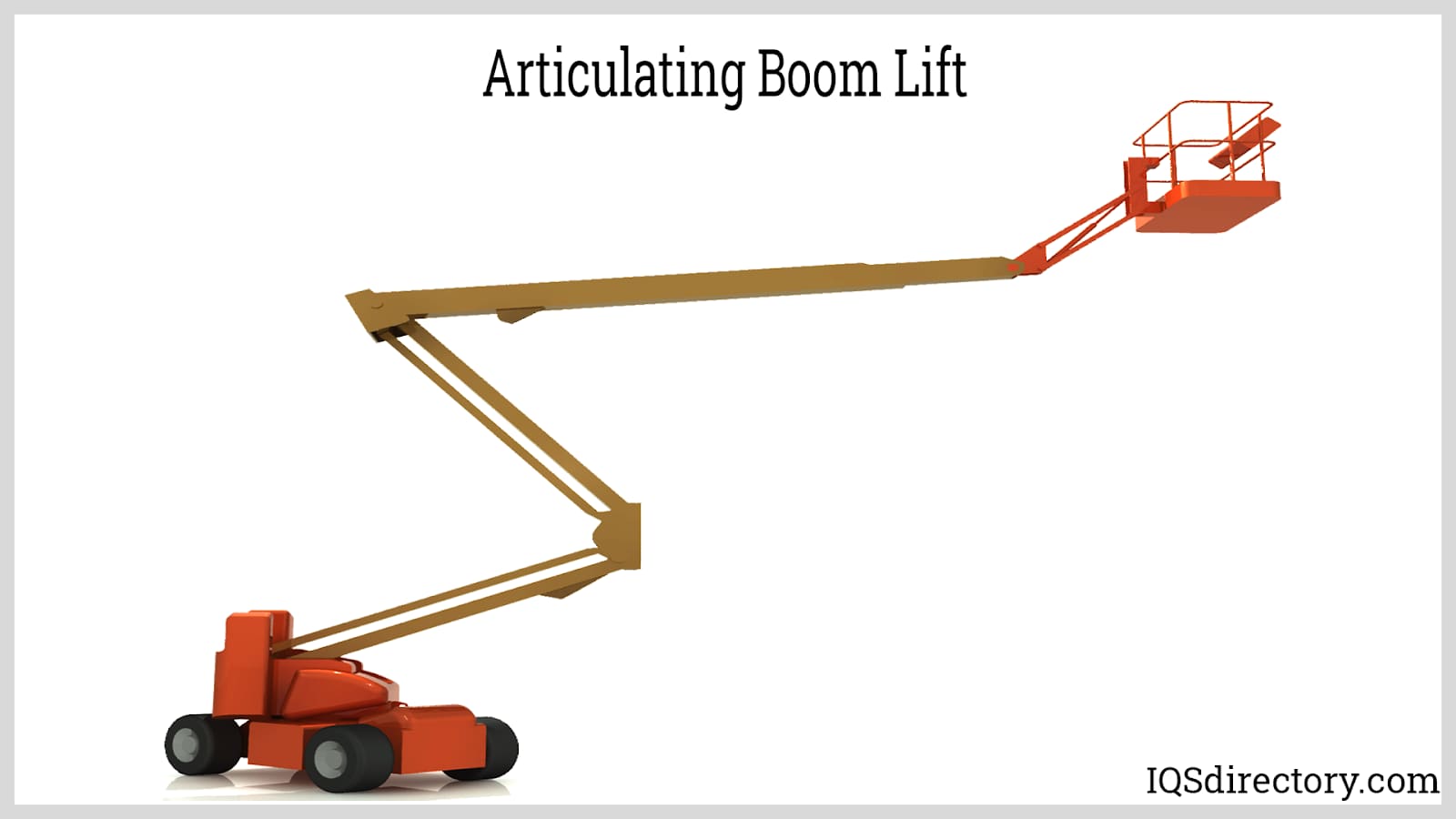

We have a wide line of vertical lifts, but customize each product for our customers’ specific applications. Vertical Reciprocating Conveyors--VRCs are for material handling only and can not be used to transport people.

At Metro Hydraulic Jack, we have been distributing pneumatic, hydraulic and mechanical equipment and tools since 1941. Our product lines include automotive lubrication systems, hydraulic tools for construction, hydraulic lifts and similar types of material handling equipment, mobile hydraulic motors and railroad lifting equipment. We also service most lines of equipment.

Isotech is a distributor of hydraulic lifts and telescopic lifting columns for medical, radiological, and industrial applications. Our columns provide a stable, reliable, and maintenance free guiding system without any play. We can customize the load, speed, and travel to meet your individual application requirements.

More Table Lift Manufacturers

Since their introduction, these handy tools have found a permanent place in factories, stores, workshops, repair shops, and manufacturing operations.

The selection of a table lift depends greatly on how it will be used. Prior to inquiring regarding its purchase, it must be decided where it will be used and its purpose. These factors determine the company from which the table will be bought since each manufacturer specializes in certain types of tables.

What is a Hydraulic Table Lift?

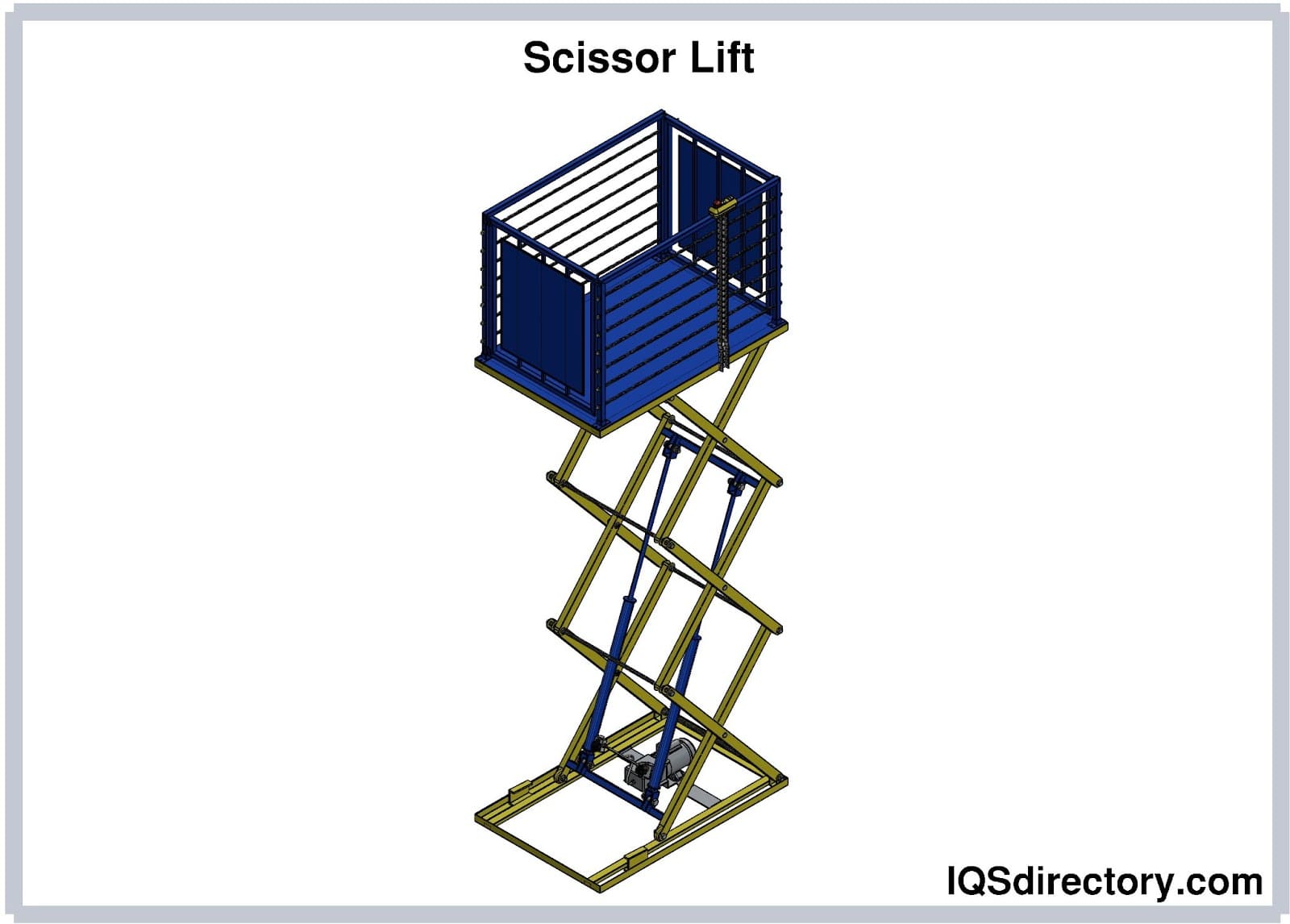

Every hydraulic lift table has set basic features, which include the number of hydraulic cylinders, platform, supports, motor, and base. Each of these components work in unison to lift and lower loads. Most hydraulic table lifts are made of some form of steel for endurance and stability.

The differentiation between hydraulic table lifts begins with the platform, which can be made of welded steel, have conveyor rollers, or be perforated. Most tables have a flat metal surface of welded steel with curved, smooth, and rounded edges. Forms that are perforated or have conveyor rollers are specialty designs.

The number of supports on the table is determined by the type of work the table will perform. Tables that are required to lift heavy loads have several thick sturdy supports that can range in number from two up to eight or ten. The number of supports is restricted by the size of the platform.

Another variation in table lifts is the type of base. For heavy duty work such as welding, engine repair, and metal work, the base will have four rigid steel supports that are tightly welded together and to the supports. Other types of lift tables have wheels and can function like a forklift.

The main part of a hydraulic table is its motor and hydraulic cylinders. Tables can have one or several hydraulic cylinders depending on the design and type of work. They are attached to the supports for raising and lowering the table. Motors can be under the platform by the cylinders, attached to the side, or a power pack. The size and type of motor is designed to fit the table’s application.

How a Hydraulic Table Lift Works –

When the motor of the table is activated, it sends a signal to the hydraulic cylinders to force oil into the cylinder to move the ram to lift the table. As the ram pushes forward, the table slowly rises and stops at the required height. How quickly the table rises depends on its load capacity, which can be a hundred pounds or several hundred pounds. Once the load is at the correct height, the rams hold secure to ensure the table does not move.

To lower the table, the motor forces the oil out of the cylinders into the reservoir and the table lowers as the rams retract. This process happens very slowly for the safety of the workers and the load.

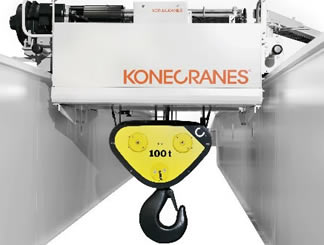

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services