Systems that rely on hydraulic power operate based on the principles of fluid mechanics, meaning that fluids are stored under pressure; when force is applied to one area it is transmitted to another area by means of the fluid. Read More…

Our hydraulic lifts are manufactured using a combination of innovation, state of the art technology, the latest engineering designs, and the highest quality products.

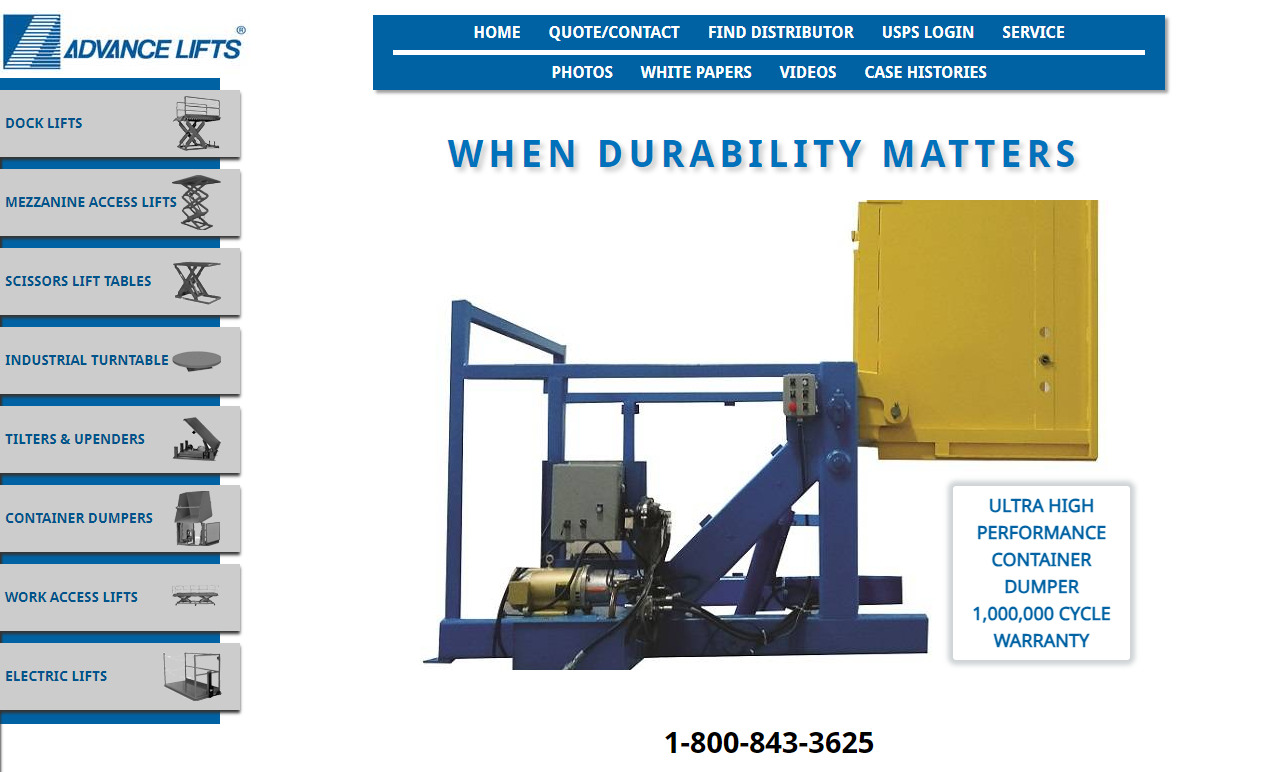

Advance Lifts designs & manufactures hydraulic lifts and other models of material handling equipment. Our ultra high-cycle lifts have a 3,000,000 cycle warranty & our patented platform centering devices reduce lift wear from off centered loading.

We manufacture hydraulic lifts and a whole lot more. Our goal is to be the best in both quality and customer service. In fact, our mission statement stays we will work hard so you can live easier.

Our hydraulic lifts are a testament to our unwavering commitment to quality and durability. Crafted with exceptional engineering, each product showcases innovative ideas that push the boundaries of what material handling equipment can achieve. We take pride in the heavy-duty materials we utilize, ensuring that our hydraulic lifts meet and exceed the demands of diverse industries.

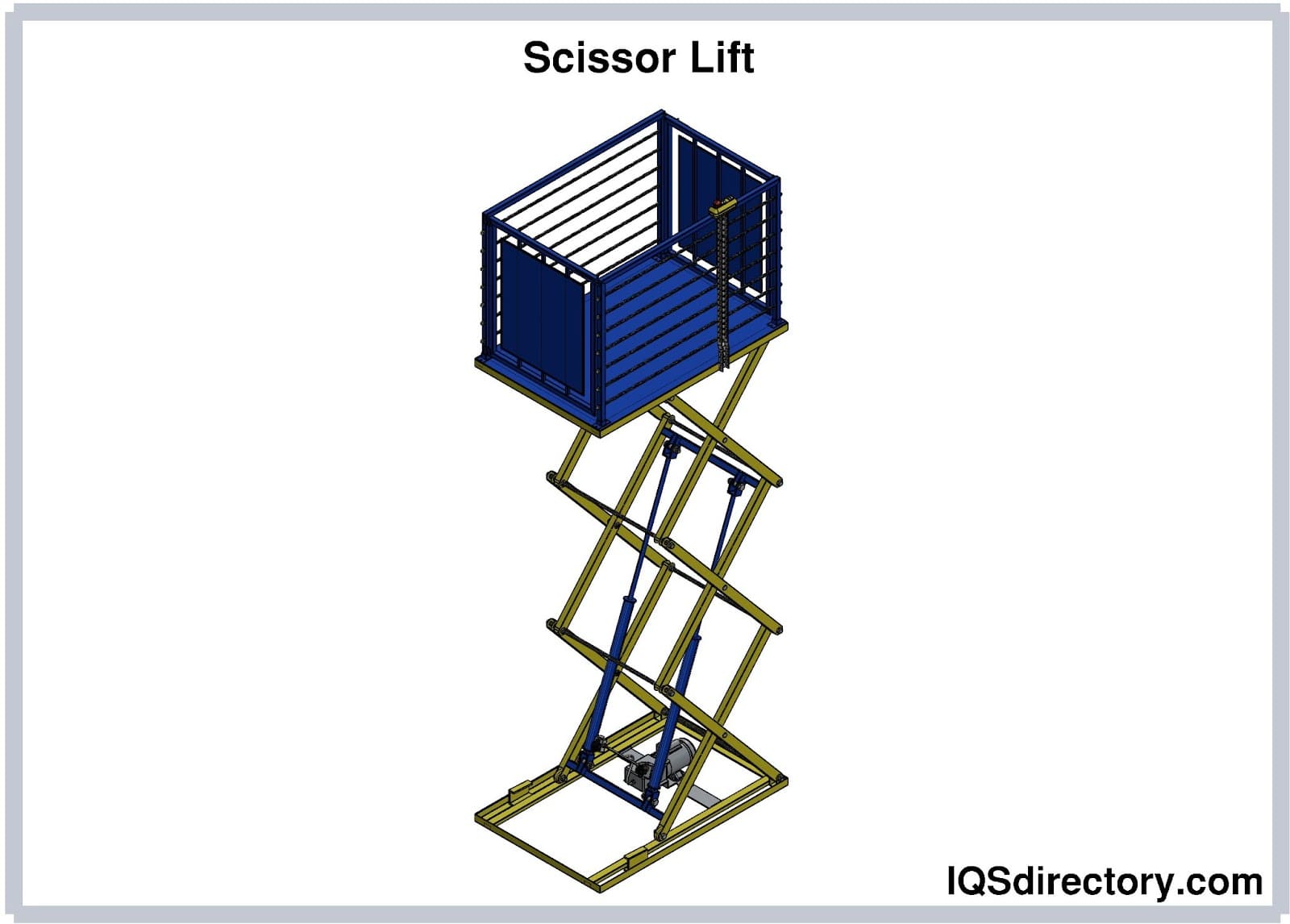

We have a wide line of vertical lifts, but customize each product for our customers’ specific applications. Vertical Reciprocating Conveyors--VRCs are for material handling only and can not be used to transport people.

At Metro Hydraulic Jack, we have been distributing pneumatic, hydraulic and mechanical equipment and tools since 1941. Our product lines include automotive lubrication systems, hydraulic tools for construction, hydraulic lifts and similar types of material handling equipment, mobile hydraulic motors and railroad lifting equipment. We also service most lines of equipment.

Isotech is a distributor of hydraulic lifts and telescopic lifting columns for medical, radiological, and industrial applications. Our columns provide a stable, reliable, and maintenance free guiding system without any play. We can customize the load, speed, and travel to meet your individual application requirements.

More Hydraulic Lift System Manufacturers

The use of fluid makes this process very efficient, and the force that is applied is in almost all cases multiplied, which makes hydraulic lifts popular for heavy-duty applications.

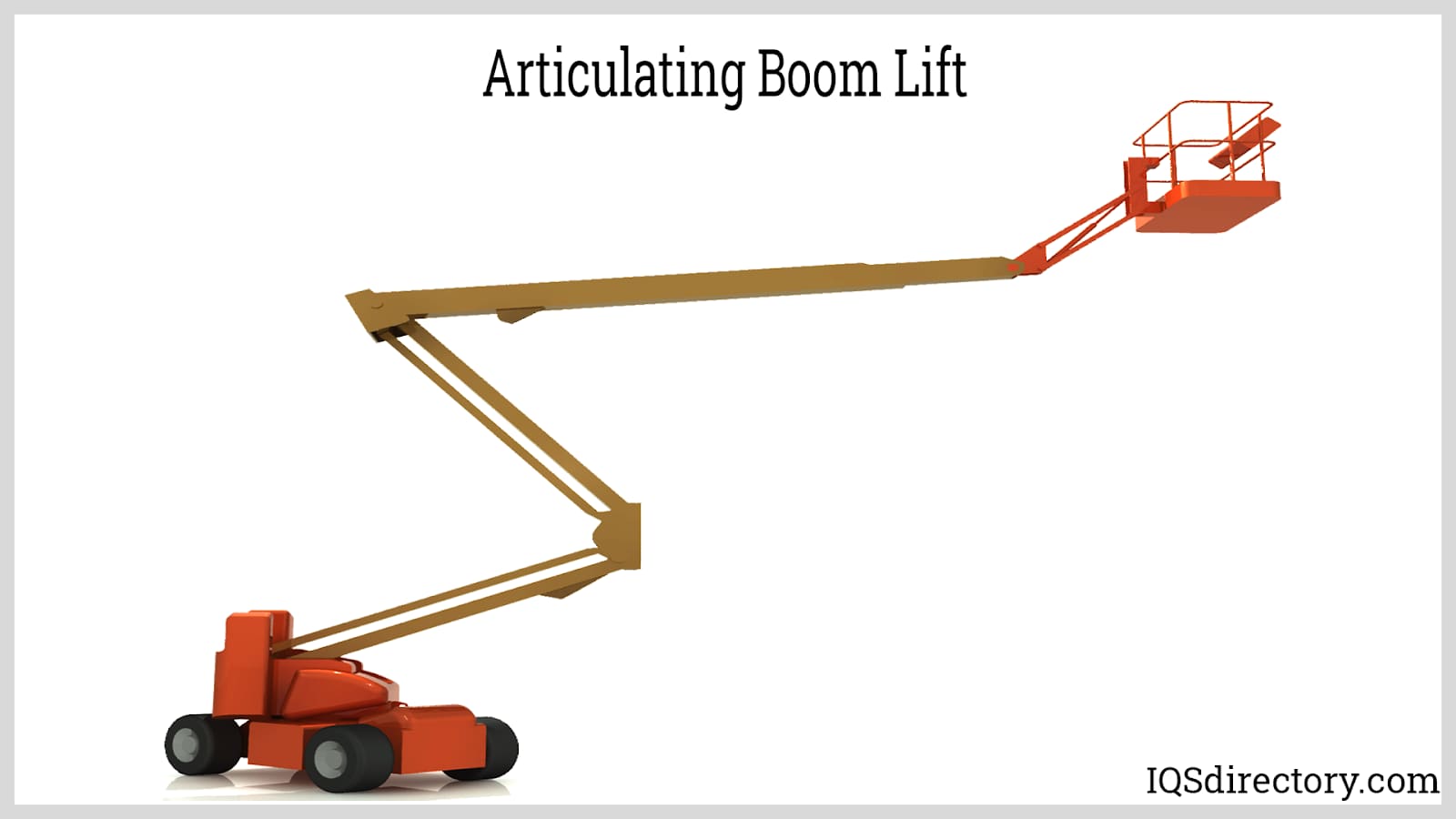

Hydraulic lift systems are frequently utilized in industries such as: automotive, for parking lift systems, braking systems and other power transmission applications; industrial manufacturing, in a variety of process and assembly machinery; construction, for the lifting of heavy building materials such as concrete, stone and brick; steel mills, for the transport and processing of steel; and marine, for applications such as off-shore mining and off-shore pipelines as well as steering and braking systems for marine vessels.

In addition, hydraulic lift systems do not require all lifts to be hydraulically-powered, but can also integrate various types of machinery that are not-powered by hydraulics; for instance, they could be electrically powered.

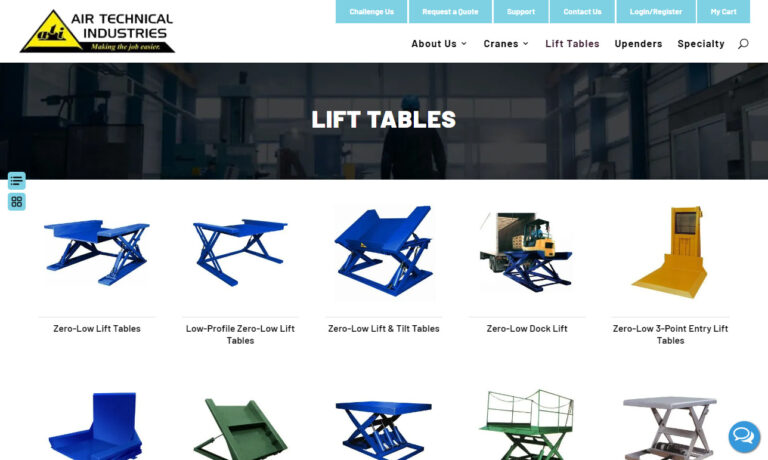

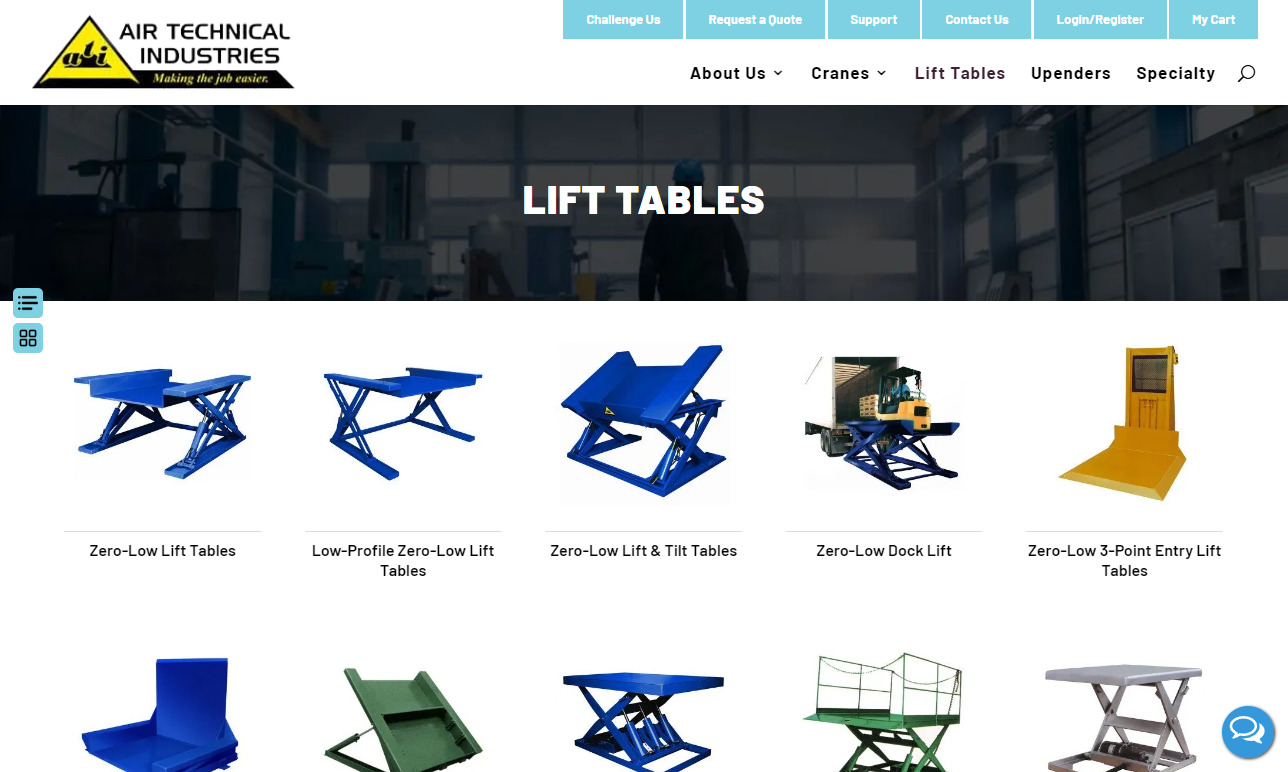

Available in a wide variety of configurations, hydraulic lift systems can be adapted to fit the specific needs of the application.

As an example, while the agricultural industry often requires large, heavy-duty hydraulic lift systems for the positioning of combine headers or plows, the medical industry requires much smaller hydraulic lift systems for use in applications such as patient, bed lifts or scooter lifts.

At their most basic, hydraulic lift systems consist of pistons, pumps, cylinders or rams and, most often, an electric battery or motor. Various types of electric batteries or motors can be used including alternating current (AC) and direct current (DC), although DC is more commonly used.

The battery powers the pistons to move and the force applied by the movement of the pistons cause the pumps to function and transport the force. The transmission of the force causes the cylinders or rams to move and provides the lifting or positioning motion. The majority of hydraulic lift systems store hydraulic energy, as in the pressurized fluids, in equipment referred to as accumulators.

Accumulators function to store the fluids under pressure in such instances that the hydraulic pump malfunctions, the engine shuts down or the pump is unable to keep up with the demand.

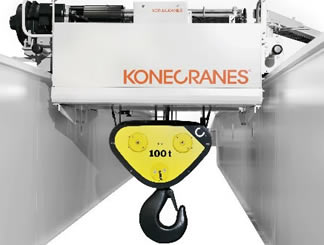

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services