Our hydraulic lifts are manufactured using a combination of innovation, state of the art technology, the latest engineering designs, and the highest quality products.

Advance Lifts designs & manufactures hydraulic lifts and other models of material handling equipment. Our ultra high-cycle lifts have a 3,000,000 cycle warranty & our patented platform centering devices reduce lift wear from off centered loading.

We manufacture hydraulic lifts and a whole lot more. Our goal is to be the best in both quality and customer service. In fact, our mission statement stays we will work hard so you can live easier.

Our hydraulic lifts are a testament to our unwavering commitment to quality and durability. Crafted with exceptional engineering, each product showcases innovative ideas that push the boundaries of what material handling equipment can achieve. We take pride in the heavy-duty materials we utilize, ensuring that our hydraulic lifts meet and exceed the demands of diverse industries.

We have a wide line of vertical lifts, but customize each product for our customers’ specific applications. Vertical Reciprocating Conveyors--VRCs are for material handling only and can not be used to transport people.

At Metro Hydraulic Jack, we have been distributing pneumatic, hydraulic and mechanical equipment and tools since 1941. Our product lines include automotive lubrication systems, hydraulic tools for construction, hydraulic lifts and similar types of material handling equipment, mobile hydraulic motors and railroad lifting equipment. We also service most lines of equipment.

Isotech is a distributor of hydraulic lifts and telescopic lifting columns for medical, radiological, and industrial applications. Our columns provide a stable, reliable, and maintenance free guiding system without any play. We can customize the load, speed, and travel to meet your individual application requirements.

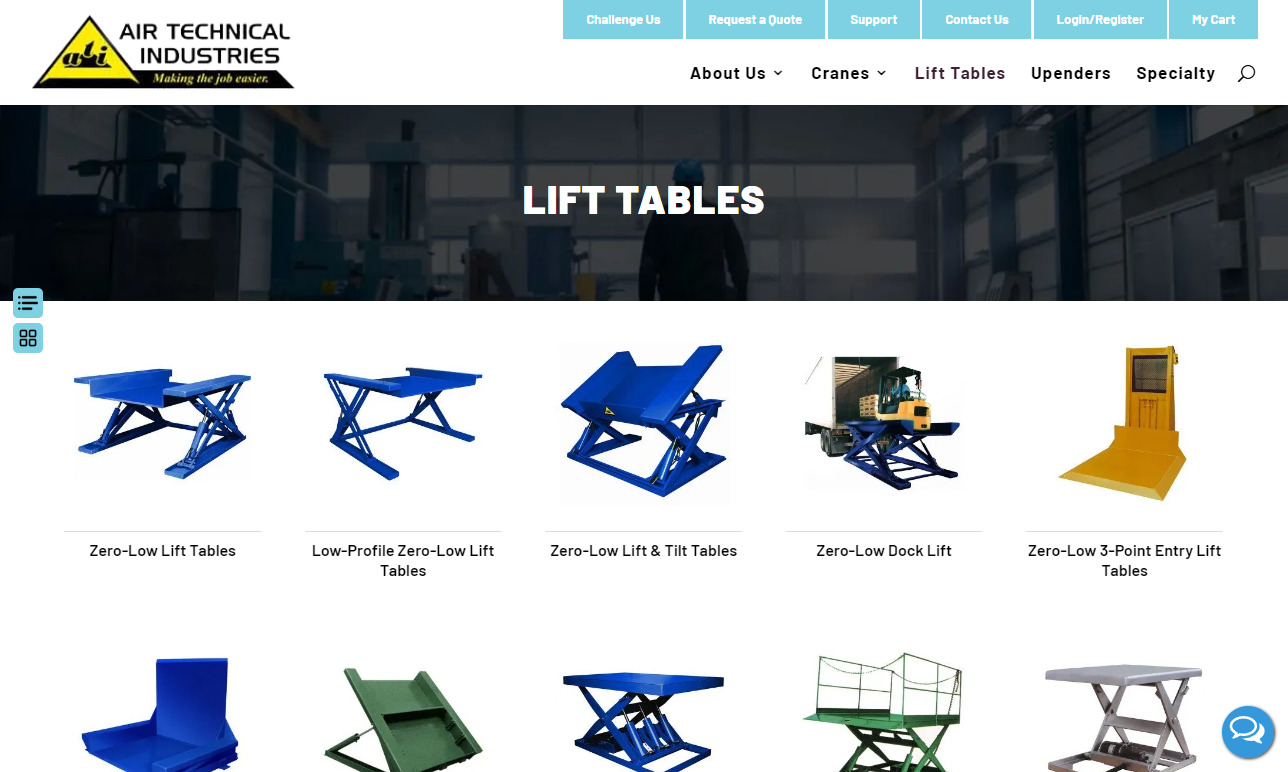

More Lift Table Manufacturers

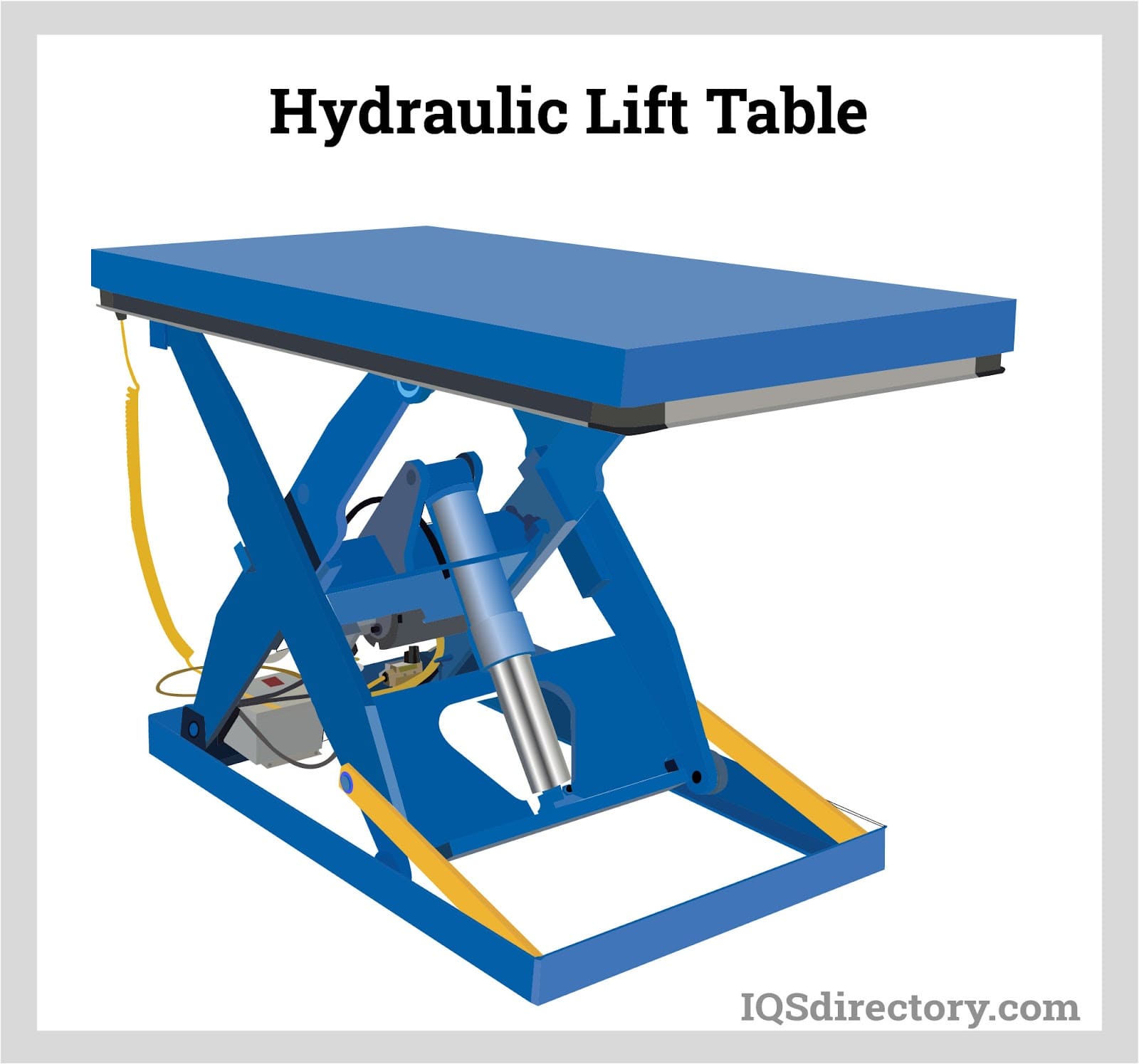

The most typical lift table design uses an electrically powered pump and hydraulic cylinders to actuate the lifting mechanism. They can be installed in a pit for floor-level loading, especially for wheelchair users, those with mobility issues, and manual pallet-pump vehicles.

Lift tables make it simple to modify them for a particular purpose. They are made of stainless steel, can operate in adverse situations, and readily have equipment like conveyors, turntables, obstacles, and gates added to their deck plates. Manufacturing upholstered furniture, metallurgy, paper, printing and publishing, warehousing and distribution, heavy machinery, and transportation are some industries that frequently use lift tables.

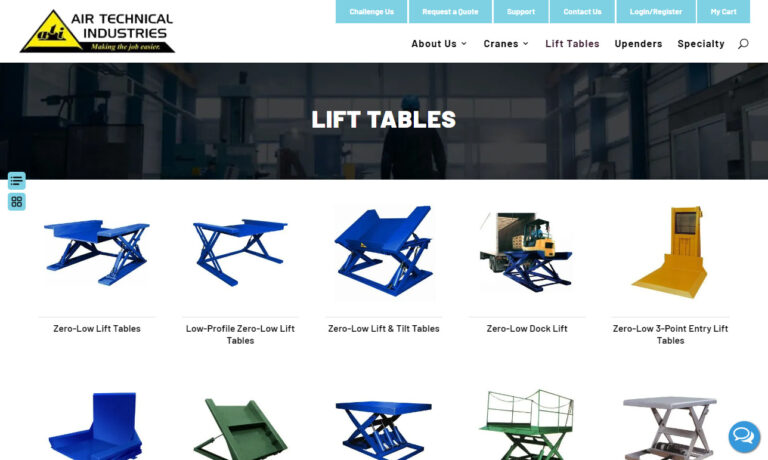

Types of Lift Tables

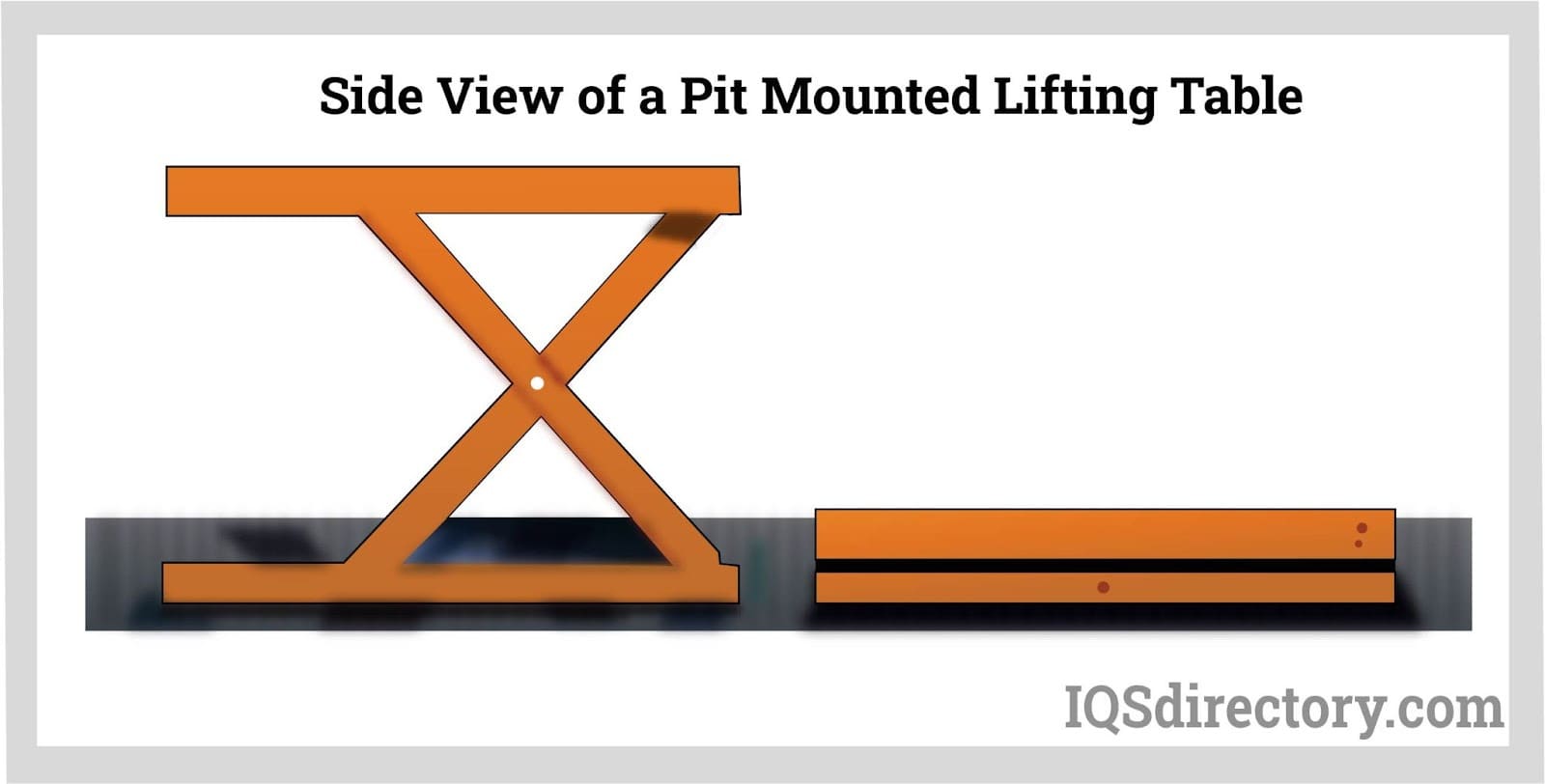

Pit-mounted Lift Tables

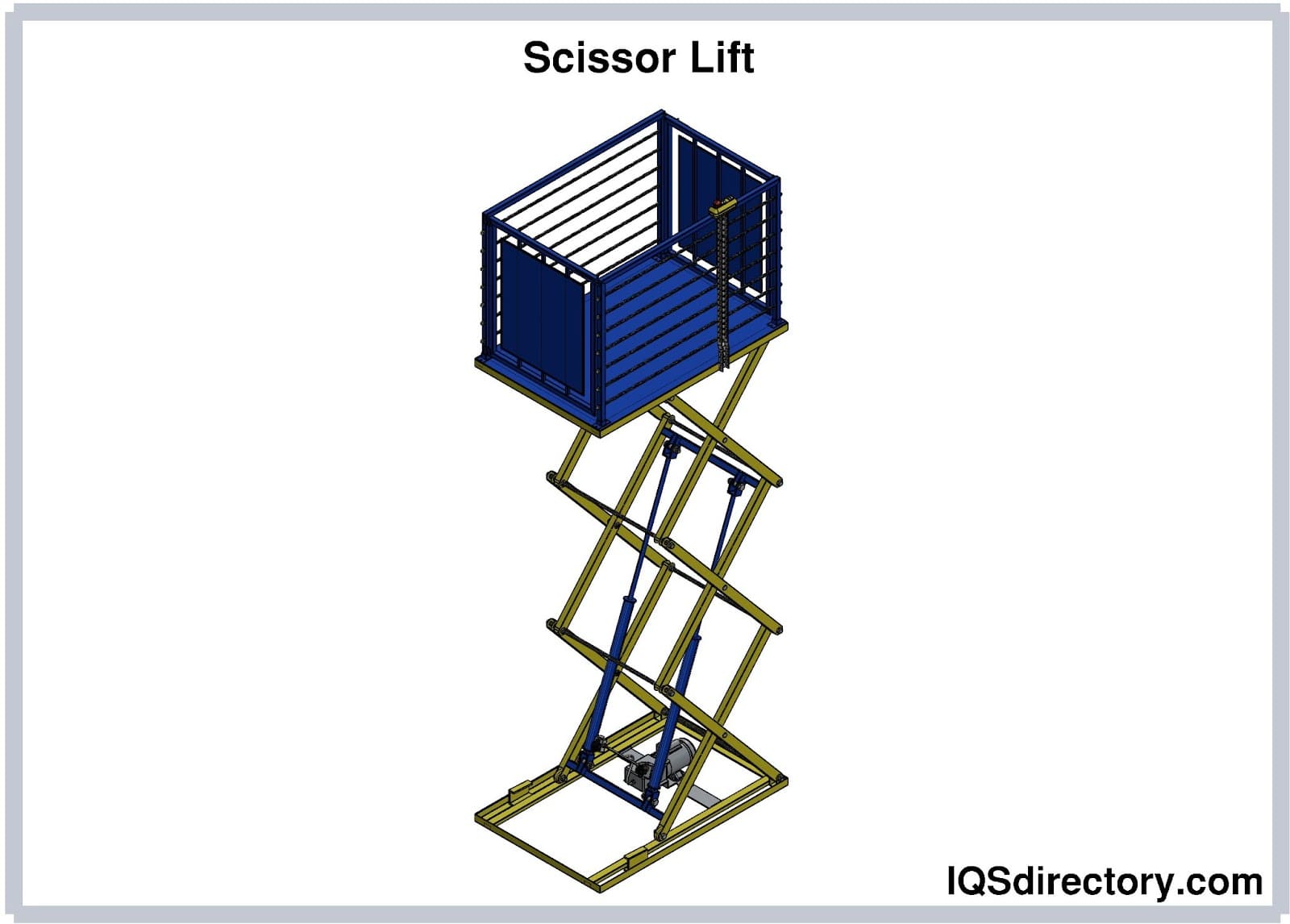

Workers can access lifting platforms from the ground thanks to pit-mounted lifting tables, flush and level with the surface or floor. It is simple and convenient for pallets or jacks to roll onto the platform. Materials are raised to a height for convenient access using a scissor lift mechanism.

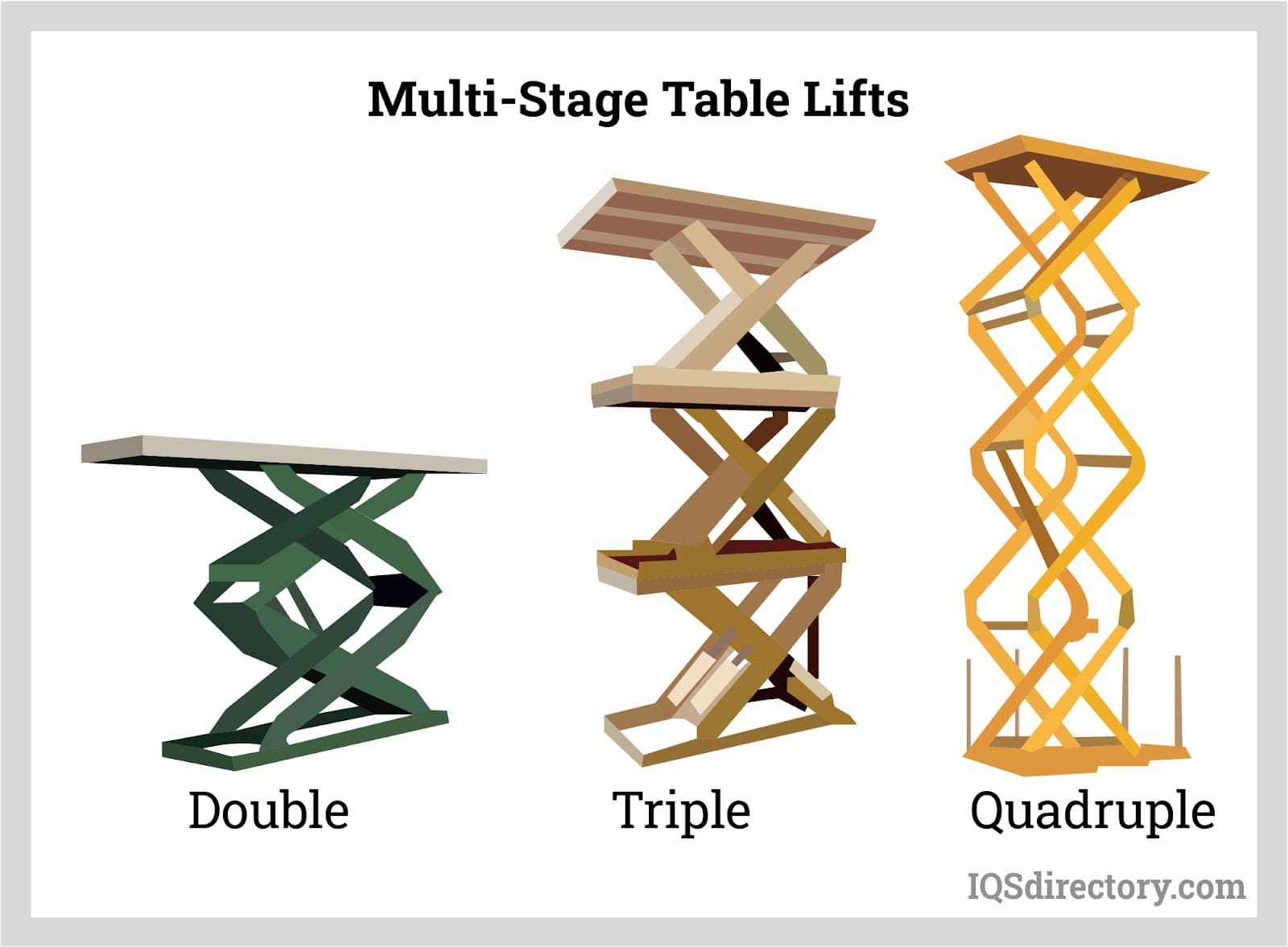

Multi-Stage Lift Tables

Multi-stage lift tables have a smaller platform but can raise themselves higher than ordinary ones. They can reach larger heights thanks to their scissor lift design, which has many sets of scissors. Multi-stage lift tables best serve applications that call for the movement to larger heights with a smaller footprint.

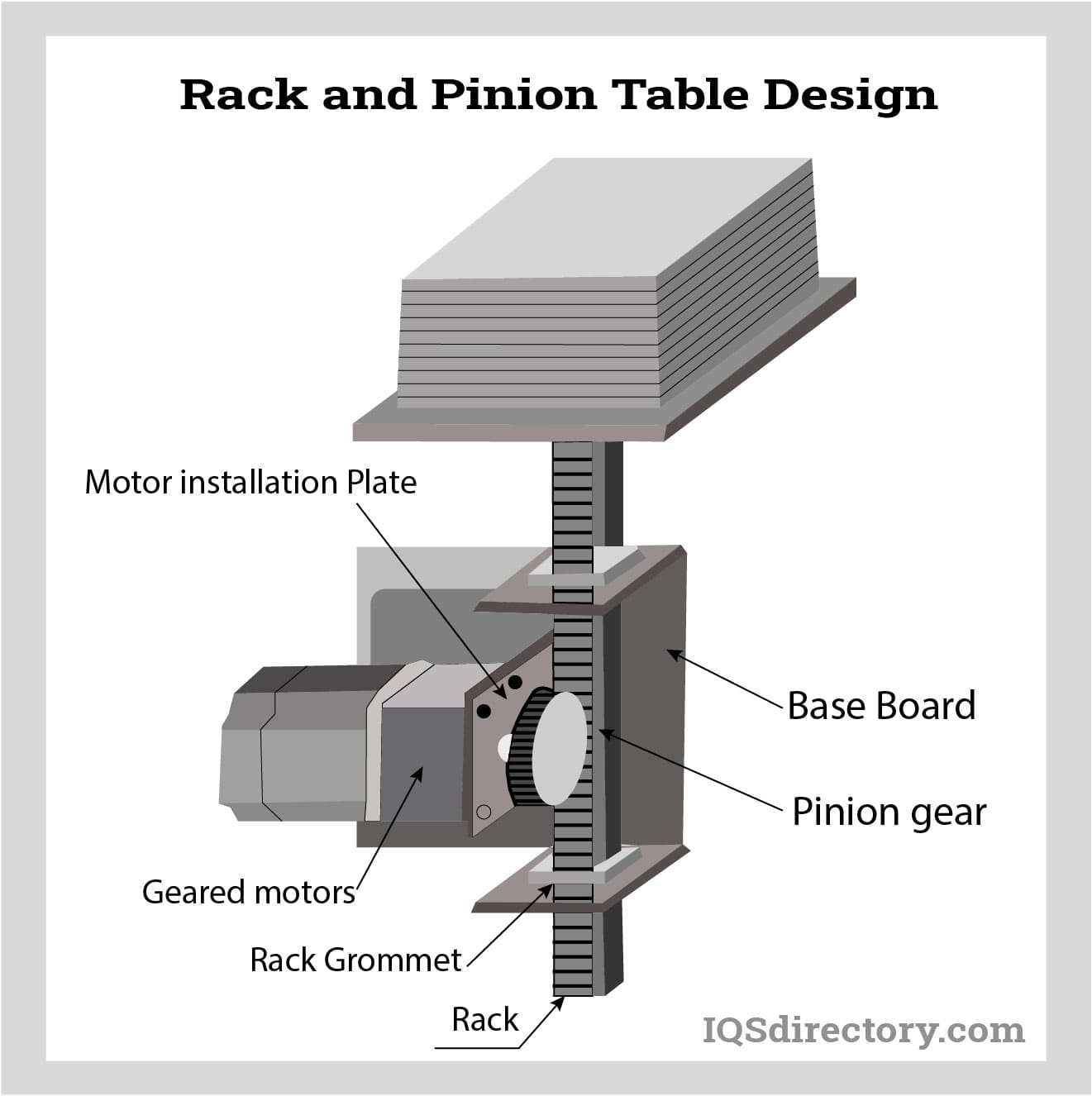

Rack Tables

The support structure restricts the length of the single rigid support used by rack and pinion lift tables. As a result, rack and pinion tables have strong construction and can lift incredibly huge loads. It has a car jack-like system with a geared electric motor that rotates the pinion gear adjusting the height of the table.

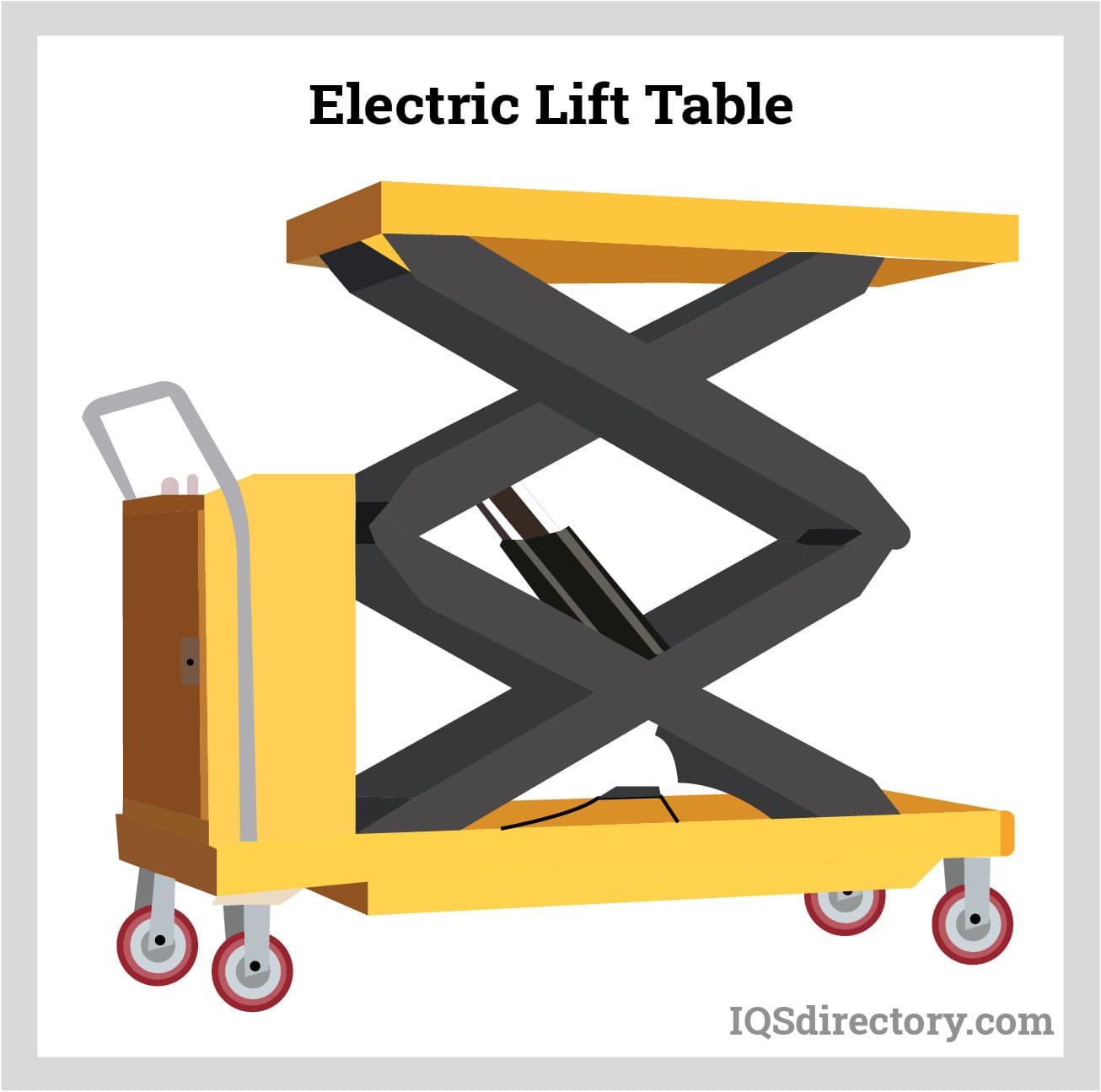

Scissor Lift Tables

Scissor-shaped arms on scissor-lift tables are used to open and close to lift and elevate the tabletop. Scissor-lifted tables may use electricity, hydraulics, or pneumatic mechanisms for power. Scissor lift tables' unique design enables them to lift massive loads while offering a solid, sturdy foundation.

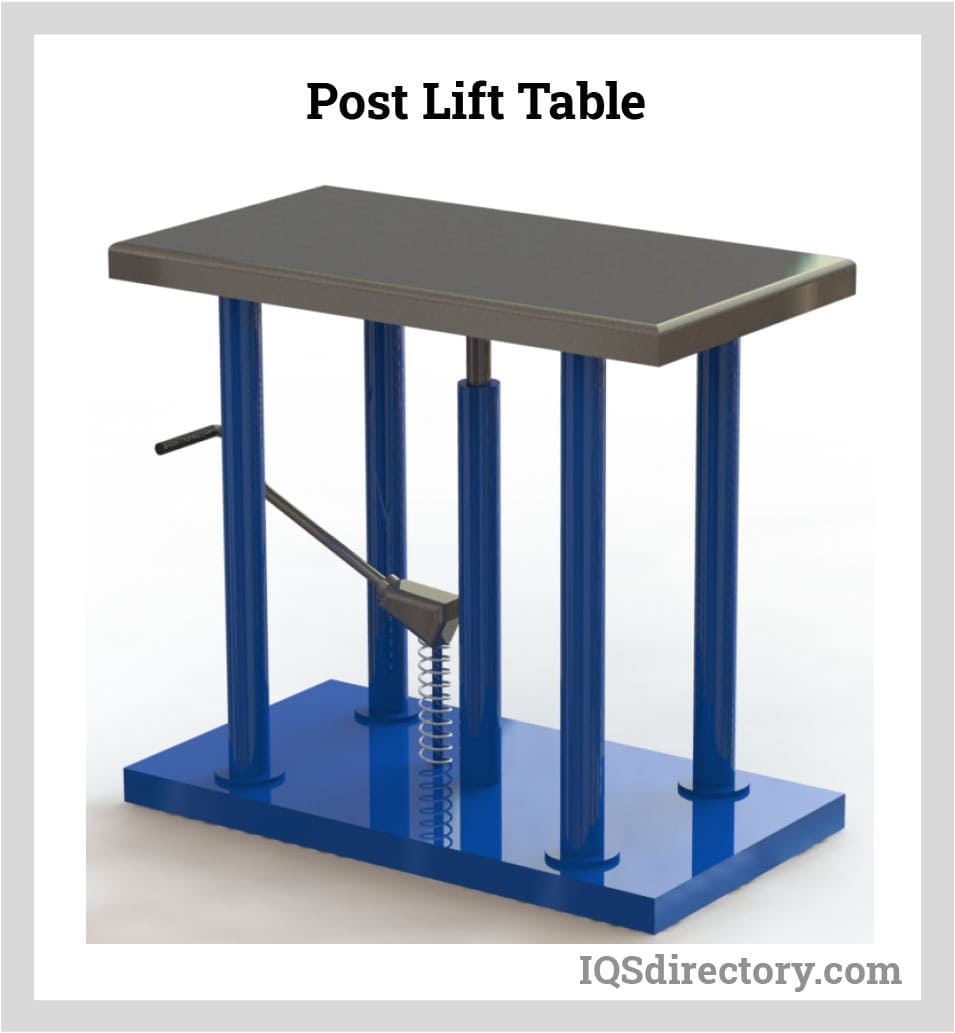

Post Lift Tables

A type of mobile lift table known as a post lift table has support posts rather than scissors. The table may be raised and lowered thanks to the posts. Post-lift tables provide an open area beneath the platform for storing and moving tools and supplies, in contrast to scissor-lift tables. A single hydraulic piston with a hand or foot pump raises the table and locks it into place.

Applications of Lift Tables

- Elevating and lowering objects when loading pallets or fulfilling orders

- Setting up packages for labeling or packing

- Car loading and unloading duties

- Assisting workers with mobility issues in factories or warehouses

- Load positioning for applications using conveyor belts

- Carrying out food processing duties in activities involving meat, poultry, and food preparation or service

- Positioning materials correctly before feeding them into machinery

- Raising or lowering huge objects that are being repaired (i.e., pieces of furniture or equipment motors)

- Lowering massive things to the ground safely

- Any activity that would ordinarily need a lot of bending or lifting

Benefits of Lift Tables

- Cut down on musculoskeletal injuries

- Keeps loads at the appropriate working heights

- Minimizes bending, stretching, and reaching

- The risk of dropping expensive goods, parts, or machinery is eliminated by lifting and lowering materials gradually and evenly. In addition, the stable platform eliminates the possibility of unsecured or swinging loads.

- Manufacturers can alter the design of lift tables to accommodate any height. When a predetermined height is attained, the table keeps that height even if the power goes out.

- One of the main benefits of using lift tables is their versatility. Several lift tables are available, each of which can be customised to match the requirements of a particular application.

- They can be positioned to offer a sturdy work surface in spaces with little available space. For example, a mobile portable lift table is the perfect answer when a large implement needs to be moved for repair but cannot be reached by a forklift.

- Lift tables can withstand all circumstances without needing to be repaired, adjusted, or updated. As a result, they will frequently operate better than every other equipment in a facility.

- Users may program the lift tables, wherein height positions, movements, and loads into the handling system are typical features of more complex lift tables.

- Lift tables' ergonomic design offers advantages beyond only reducing muscle soreness. Every application needs a certain level of mental fortitude to finish. Lift tables' versatility alleviates many workers' worries when they have to complete a task requiring a large load.

- With the advent of multi-stage lift tables, lift tables' vertical range is now infinite. With the right safety precautions, lift tables can function like elevators and transport workers to any height within a building.

Choosing the Correct Lift Table Supplier

To ensure you have the most positive outcome when purchasing a lift table from a lift table supplier, it is important to compare several companies using our directory of lift table suppliers. Each lift table supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each lift table business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple lift table companies with the same form.

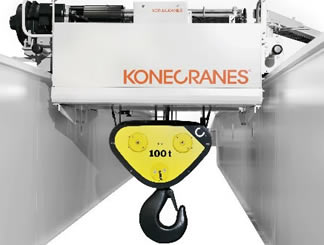

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services