Pneumatics is the control and transfer of power using compressed air. Machines require the use of compressors, pistons, actuators, valves to control the air and reservoirs to store the air. Read More…

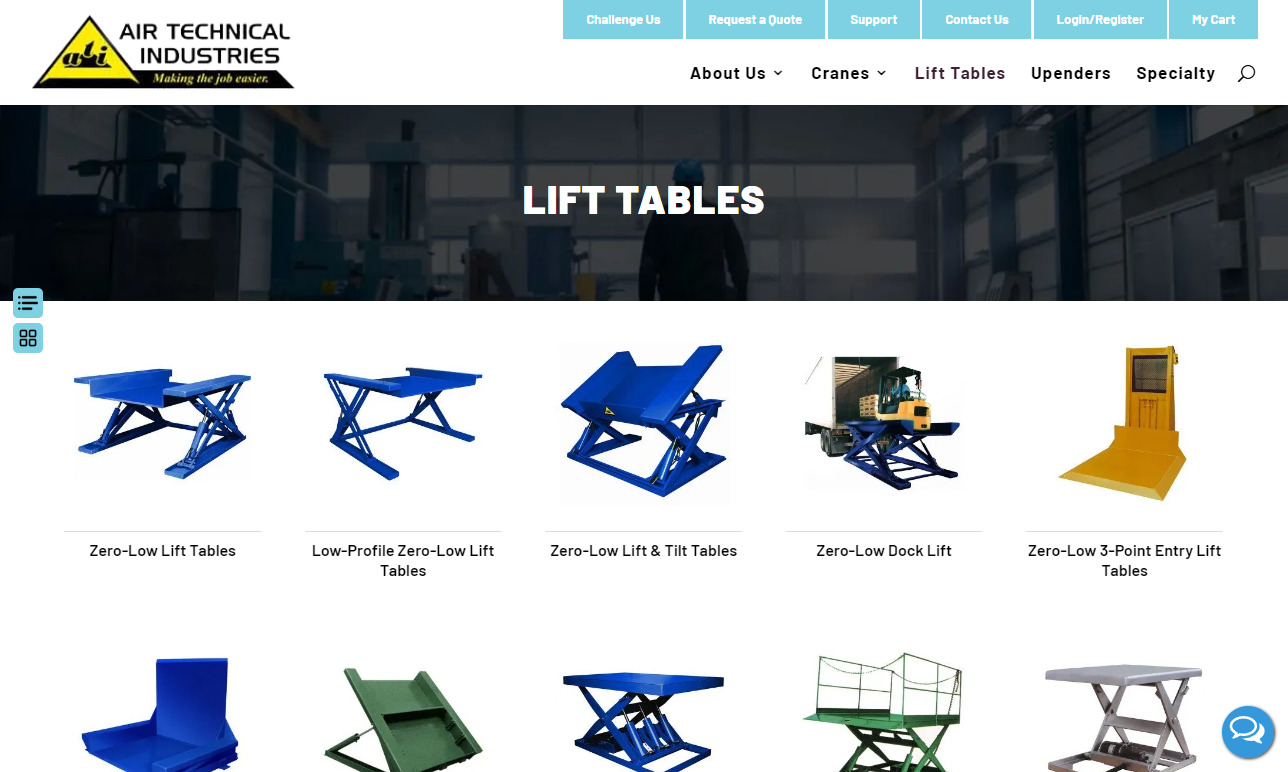

Our hydraulic lifts are manufactured using a combination of innovation, state of the art technology, the latest engineering designs, and the highest quality products.

Advance Lifts designs & manufactures hydraulic lifts and other models of material handling equipment. Our ultra high-cycle lifts have a 3,000,000 cycle warranty & our patented platform centering devices reduce lift wear from off centered loading.

We manufacture hydraulic lifts and a whole lot more. Our goal is to be the best in both quality and customer service. In fact, our mission statement stays we will work hard so you can live easier.

Our hydraulic lifts are a testament to our unwavering commitment to quality and durability. Crafted with exceptional engineering, each product showcases innovative ideas that push the boundaries of what material handling equipment can achieve. We take pride in the heavy-duty materials we utilize, ensuring that our hydraulic lifts meet and exceed the demands of diverse industries.

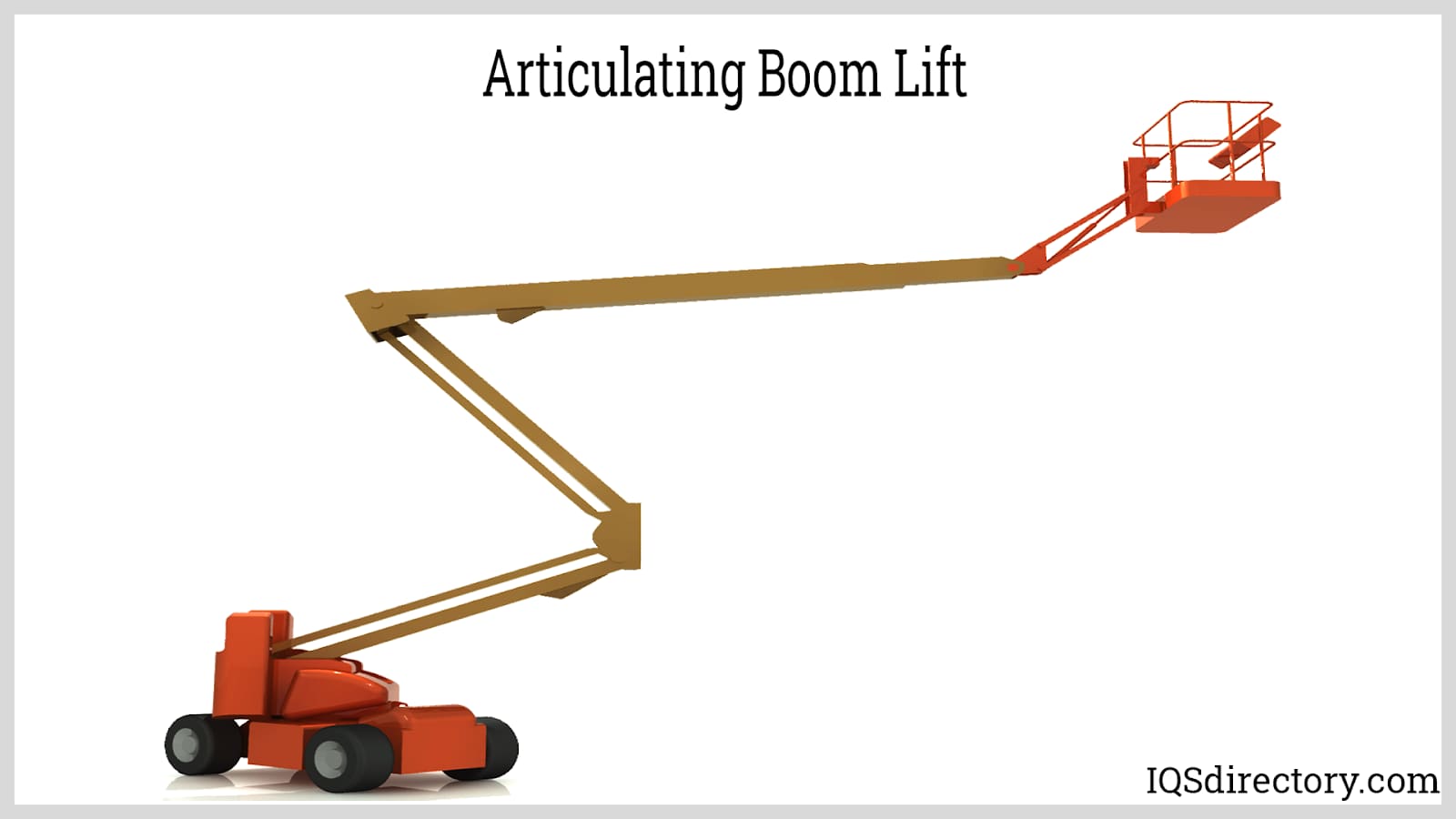

We have a wide line of vertical lifts, but customize each product for our customers’ specific applications. Vertical Reciprocating Conveyors--VRCs are for material handling only and can not be used to transport people.

At Metro Hydraulic Jack, we have been distributing pneumatic, hydraulic and mechanical equipment and tools since 1941. Our product lines include automotive lubrication systems, hydraulic tools for construction, hydraulic lifts and similar types of material handling equipment, mobile hydraulic motors and railroad lifting equipment. We also service most lines of equipment.

Isotech is a distributor of hydraulic lifts and telescopic lifting columns for medical, radiological, and industrial applications. Our columns provide a stable, reliable, and maintenance free guiding system without any play. We can customize the load, speed, and travel to meet your individual application requirements.

More Pneumatic Lift Manufacturers

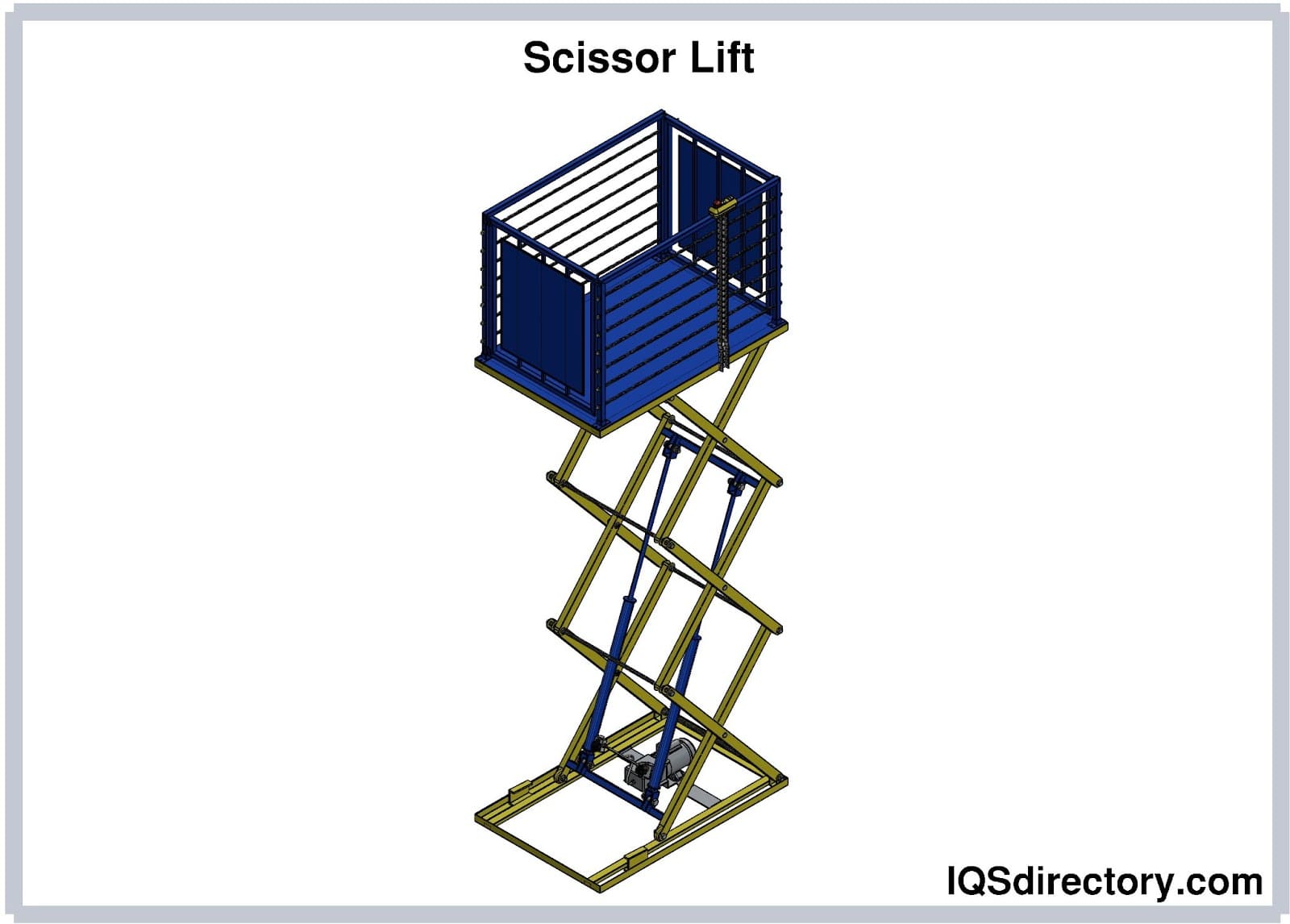

Pneumatic lifts use pressurized air to lift items higher or move them up floors. Pneumatics are used over electric or hydraulic for their low cost. However, they cannot get as high as their counterparts due to air being a weaker power source. An external pump increases internal pressure inside the lift, which allows the cylinder the move along the axis of the piston.

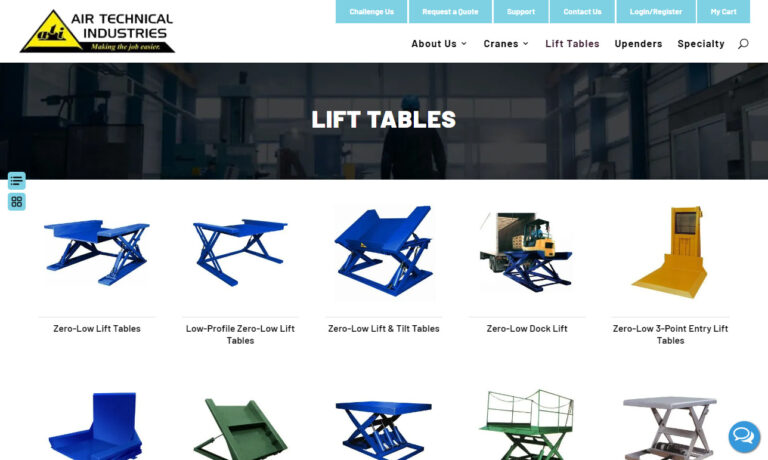

Pneumatic lifts employ a lifting mechanism using a hollow cylinder and a piston. As the piston moves, air pressure is increased, which causes the lift components to raise. Pneumatic lifts are used to assist in raising large or heavy loads during pallet handling or vehicle loading. The versatility allows for assisting in work positioning and ergonomic handling of goods, reducing incidents of musculoskeletal disorders in workers. Industries that commonly use lift tables include woodworking, upholstered furniture manufacturing, metalworking, paper, printing and publishing, warehousing and distribution, heavy machinery and transportation.

TypesThere are two basic types of Pneumatic lifts. The air over hydraulic, which are built the same as a traditional lift except that the electric motor is replaced by an air motor. Lifts of this type are used in applications where electrical components cannot be used or are not available. The other type is the airbag design which operates by inflating airbags under the table to cause lift. Pneumatic scissor lifts use air pressure as their lifting mechanism. Often chosen because these lifts do not emit hazardous fumes or by-products into the environment.

Pneumatics are often used because they are more cost-effective than electric lifts. However, because of their actuator size, operating pressure may be difficult to maintain. Making the lifts not ideal when high reliability is required.

To ensure safety it is recommended to examine lifts every 6 to 12 months, depending on the equipment. Additionally, lifts according to LOLER Approved Code of Practice and guidance must be examined by a competent person. Competent being defined as someone with appropriate practical and theoretical knowledge and experience of lifting equipment. A LOLER examination is required at least once a year under the Health & Safety legislation.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services