Small hydraulic lifts are hydraulic lifts with average industry size; thus, their use is generally for small-scale applications. They are also known as miniature hydraulic lifts. Small hydraulic lifts are used for moving and holding products, and they can be controlled remotely or manually. Read More…

Our hydraulic lifts are manufactured using a combination of innovation, state of the art technology, the latest engineering designs, and the highest quality products.

Advance Lifts designs & manufactures hydraulic lifts and other models of material handling equipment. Our ultra high-cycle lifts have a 3,000,000 cycle warranty & our patented platform centering devices reduce lift wear from off centered loading.

We manufacture hydraulic lifts and a whole lot more. Our goal is to be the best in both quality and customer service. In fact, our mission statement stays we will work hard so you can live easier.

We have a wide line of vertical lifts, but customize each product for our customers’ specific applications. Vertical Reciprocating Conveyors--VRCs are for material handling only and can not be used to transport people.

Our hydraulic lifts are a testament to our unwavering commitment to quality and durability. Crafted with exceptional engineering, each product showcases innovative ideas that push the boundaries of what material handling equipment can achieve. We take pride in the heavy-duty materials we utilize, ensuring that our hydraulic lifts meet and exceed the demands of diverse industries.

At Metro Hydraulic Jack, we have been distributing pneumatic, hydraulic and mechanical equipment and tools since 1941. Our product lines include automotive lubrication systems, hydraulic tools for construction, hydraulic lifts and similar types of material handling equipment, mobile hydraulic motors and railroad lifting equipment. We also service most lines of equipment.

Isotech is a distributor of hydraulic lifts and telescopic lifting columns for medical, radiological, and industrial applications. Our columns provide a stable, reliable, and maintenance free guiding system without any play. We can customize the load, speed, and travel to meet your individual application requirements.

More Small Hydraulic Lift Manufacturers

What are Small Hydraulic Lifts?

Small hydraulic lifts are compact yet robust lifting devices that utilize fluid power to raise, lower, or move loads efficiently in a wide variety of industrial, commercial, and residential settings. Despite their compact size, small hydraulic lifts are renowned for their high strength, durability, and versatility. They deliver reliable lifting solutions where space is limited or where precise, controlled movement is required, making them a preferred choice across multiple industries seeking efficient and cost-effective material handling equipment.

Whether for industrial manufacturing, warehouse logistics, automotive workshops, or home accessibility, small hydraulic lifts offer powerful lifting capacity in a compact footprint. Their adaptability and ease of use make them an essential part of modern material handling and ergonomic workspaces.

How Small Hydraulic Lifts Function

Understanding the working principle of small hydraulic lifts is key for anyone evaluating lifting equipment for purchase or installation. At their core, these lifts operate on the principles of hydraulic fluid mechanics — specifically, Pascal’s Law. This law states that when pressure is applied to a confined fluid, the pressure change is transmitted undiminished throughout the fluid.

In practice, small hydraulic lifts feature a reservoir (often containing oil), a pump, and one or more hydraulic cylinders. When an operator actuates the lift by pressing a button, turning a switch, or using a manual lever, the pump forces hydraulic fluid into the cylinder. This pressurized fluid moves a piston, which then lifts the platform or load. Because of the force multiplication effect in hydraulics, a relatively small input force can lift a much heavier load, making hydraulic lifts extremely efficient and powerful for their size.

The materials used in small hydraulic lifts are chosen for their ability to withstand high pressure and heavy-duty cycles. Common materials include high-grade steel, reinforced rubber, and woven wire mesh. Many small hydraulic lifts are also engineered with mobility in mind, featuring rugged wheels or casters for easy relocation around a facility, while others are designed for stationary installation.

Looking for more technical details or maintenance tips? Explore our hydraulic lift FAQ section below for answers to common technical and operational questions.

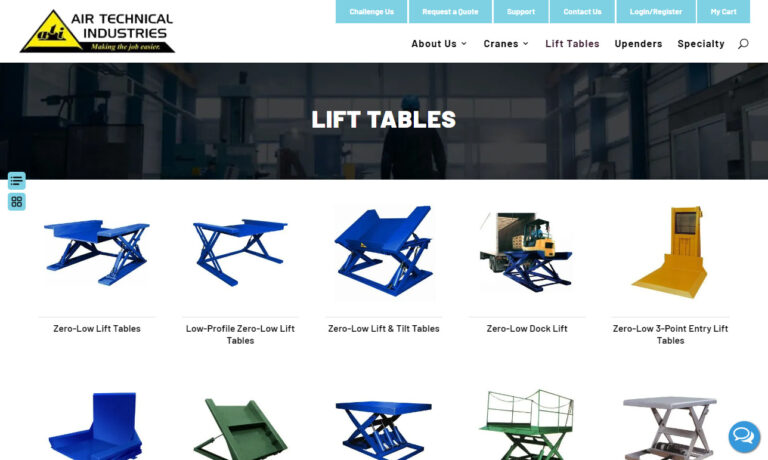

Types of Small Hydraulic Lifts

There are several types of small hydraulic lifts available on the market, each engineered to address specific lifting needs, load capacities, and operational environments. Selecting the right type depends on the intended application, required lift height, load weight, and whether mobility or stationary use is preferred.

Portable Hydraulic Lift

Portable hydraulic lifts are compact, lightweight, and engineered for rapid deployment and easy operation. With a load capacity of up to 250 pounds (113.4 kg) and a maximum lift height of 48 inches (121.9 cm), these units are ideal for environments where flexibility and maneuverability are essential.

Commonly used for machine feeding, component assembly, inspection, and mobile staging, portable hydraulic lifts can be customized with tool holders, fixtures, or specialized platforms to streamline workflow and minimize operator fatigue. Their mobility makes them invaluable in warehouses, production lines, and service centers where tasks and workstations shift frequently.

Small Electric Hydraulic Person Lifts

Small electric hydraulic person lifts are specifically designed for the safe elevation of personnel to desired working heights. These lifts are self-supporting, compact, and can be powered via standard 120 VAC outlets, making them highly convenient for indoor use and maintenance tasks. Common applications include assembly operations, overhead maintenance, electrical installations, and routine inspections where safety and efficiency are paramount.

When evaluating person lifts, key considerations include platform size, lift height, load capacity, safety features (such as guardrails and emergency stop switches), and ease of transport. Modern designs prioritize operator safety and comply with strict occupational safety standards.

Small Electric Hydraulic Lift Carts

Portable electric hydraulic lift carts deliver exceptional durability, safety, and operational flexibility to facilities requiring frequent movement of products or materials. Powered by 12 V direct current (DC) systems, these carts are ideal for light-duty applications such as material loading/unloading, product assembly, and order picking.

Lift carts are available in various platform sizes and weight capacities, often featuring ergonomic controls, safety locks, and easy-to-maneuver wheels. Their compact design helps reduce workplace injuries related to manual lifting and repetitive strain, promoting a safer and more productive environment.

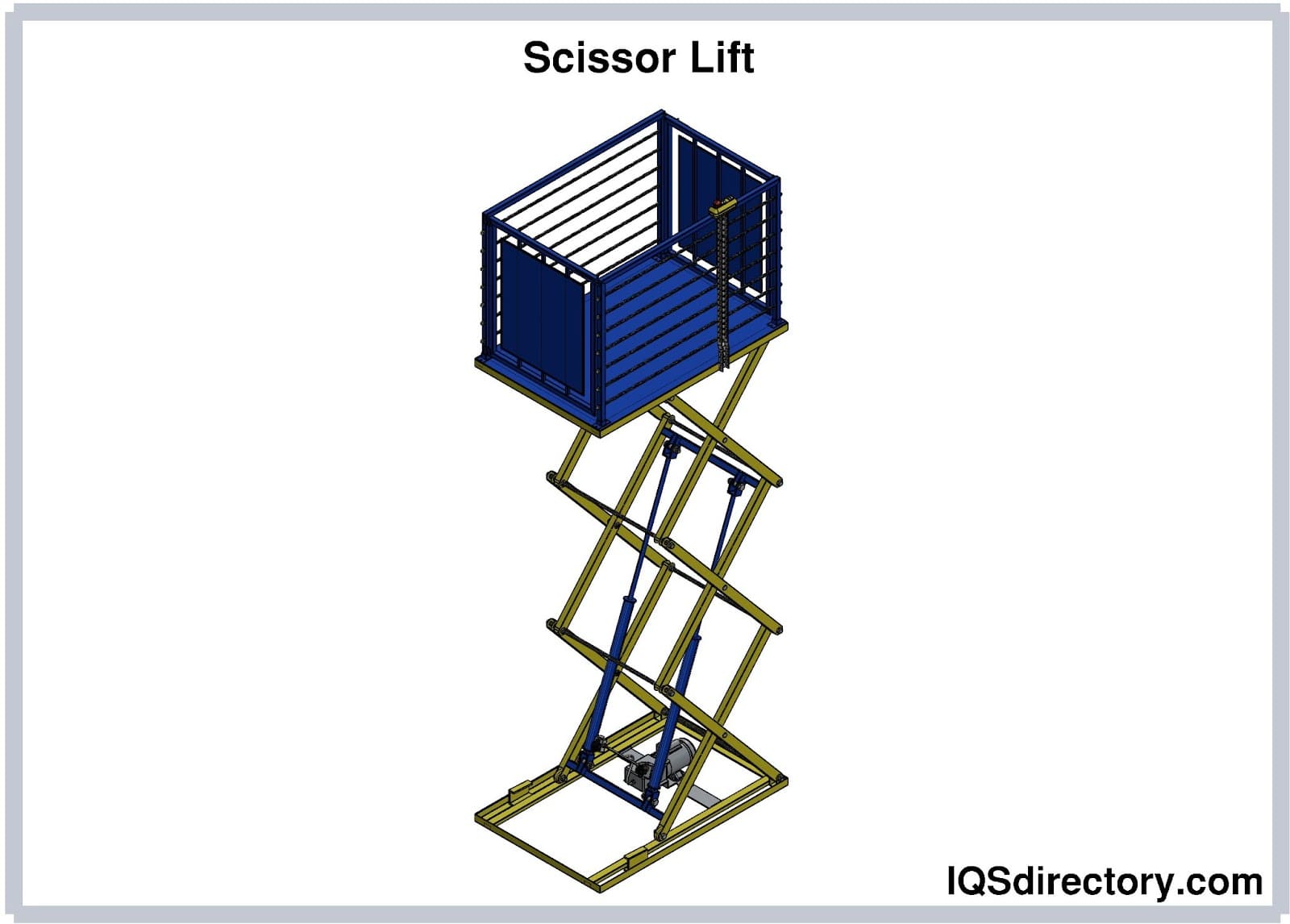

Small Hydraulic Scissor Lift

Small hydraulic scissor lifts employ a cross-braced, folding mechanism that allows for stable vertical movement. The base of the lift ensures a stable foundation while one to three hydraulic cylinders provide the lifting force. These lifts are highly valued for their ability to handle surprisingly heavy loads despite their modest footprint, making them a go-to choice for tight spaces and low-ceiling environments.

Scissor lifts are frequently used in warehousing, logistics, automotive repair, and manufacturing settings for tasks such as pallet handling, vehicle maintenance, and equipment positioning. Their durable construction and straightforward operation translate into long service life and reduced downtime.

Specialized Small Hydraulic Lifts

Beyond these primary categories, manufacturers offer a range of specialized small hydraulic lifts tailored for niche applications, such as:

- Hydraulic lift tables for ergonomic work positioning

- Dock lifts for loading and unloading trucks

- Hydraulic wheelchair lifts for accessibility in public and private buildings

- Hydraulic platform lifts for stage and theater use

- Hydraulic stackers for compact pallet handling

Not sure which hydraulic lift is right for your application? Contact our team or consult our buyer's guide below for personalized recommendations.

Applications and Benefits of Small Hydraulic Lifts

Small hydraulic lifts are indispensable in a broad spectrum of industries due to their adaptability, reliability, and efficiency. If you’re exploring how these lifts can optimize your specific workflow, consider the following use cases and advantages:

Applications of Small Hydraulic Lifts

Small hydraulic lifts provide a practical solution for safely raising and lowering goods, personnel, and equipment. Key usage areas include:

- Automotive shops – Vehicle component handling, engine assembly, and maintenance tasks

- Construction sites – Material transport, installation support, and worker elevation

- Shipping and logistics – Loading/unloading pallets, order picking, and inventory management

- Waste removal and recycling – Efficient bin and container emptying

- Mining and heavy industry – Equipment maintenance, underground support, and safe material movement

- Retail and warehousing – Stock replenishment, shelf restocking, and product display arrangement

- Healthcare and accessibility – Wheelchair lifts, patient transfer aids, and ergonomic workstations

- Manufacturing – Production line integration, assembly support, and work positioning

- Home and residential – Stair lifts, dumbwaiters, and small platform lifts for accessibility

Curious about hydraulic lift applications in your industry? Search our industry use case library for more detailed examples and case studies.

Benefits of Small Hydraulic Lifts

- Low maintenance requirements: Hydraulic lifts have fewer moving parts than mechanical alternatives, reducing wear and the need for frequent servicing.

- Cost-effective installation: Most small hydraulic lifts are less expensive to install compared to traditional elevators or mechanical lifts, making them attractive for budget-conscious projects.

- Space efficiency: Their compact design and smaller shaft requirements (up to 10% less space) help maximize usable floor area in buildings and facilities.

- No separate machine room needed: Many small hydraulic lifts are designed with integrated or remote power units, eliminating the need for a dedicated machine room and further conserving space.

- Flexible placement: Hydraulic lifts can be installed in a wide variety of environments, including retrofits in existing structures and mobile applications.

- Enhanced safety: Safety features such as emergency lowering, overload protection, and anti-slip platforms are standard in most modern designs.

- Precision control: Hydraulic systems allow for smooth, accurate lifting and lowering, essential for delicate operations or when positioning heavy loads with care.

- Energy efficiency: Hydraulic lifts consume power only during lifting, not lowering, helping to reduce operating costs.

Drawbacks of Small Hydraulic Lifts

- Slower lifting speeds: Hydraulic lifts are typically limited to speeds of 150 feet per minute or less, making them less suitable for high-speed transport between floors.

- Heat buildup: Prolonged or heavy use can cause the hydraulic fluid to overheat, necessitating efficient temperature management systems.

- Potential for fluid leakage: Regular inspection and maintenance are required to prevent and address hydraulic oil leaks, which can affect performance and workplace safety.

- Odor concerns: Overused or overheated hydraulic fluid may emit unpleasant odors.

- Ride quality: Some users may perceive hydraulic lifts as less smooth than traction or screw-driven alternatives, which may be a consideration for certain applications.

Weighing the pros and cons? See our guide below for decision-making tips and a checklist of key factors to consider before purchasing.

Choosing the Right Small Hydraulic Lift Supplier

Selecting the right small hydraulic lift supplier is critical to ensuring product quality, safety, and long-term value. Here are the primary factors to consider when evaluating suppliers and manufacturers:

- Industry expertise and reputation: Look for suppliers with a strong track record in hydraulic lift manufacturing, positive customer reviews, and relevant industry certifications.

- Customization capabilities: Many applications require tailored solutions. Assess whether the supplier can modify platform size, lifting capacity, controls, and safety features to meet your specific requirements.

- Product range and availability: A diverse inventory of lift types, weight capacities, and configurations ensures you can find the ideal match for your needs.

- Safety and compliance: Ensure all lifts comply with local, national, and international safety standards—such as ANSI, ASME, or CE certifications.

- Support and after-sales service: Choose suppliers that offer installation, training, maintenance, and rapid parts replacement to minimize downtime and maximize ROI.

- Warranty coverage: Comprehensive warranties reflect confidence in product quality and offer peace of mind for your investment.

- Lead times and delivery: Fast, reliable shipping and clear communication on lead times help keep your project on schedule.

- Price transparency: Obtain detailed quotes and compare costs, but also factor in the total cost of ownership, including maintenance and energy usage.

To ensure you achieve the most beneficial outcome when purchasing a small hydraulic lift, compare multiple suppliers using our comprehensive directory of small hydraulic lift manufacturers and suppliers. Each supplier has a dedicated business profile page highlighting their strengths, experience, and capabilities, along with a contact form for direct inquiries or quote requests.

Need to quickly compare options? Use our proprietary website previewer to review each small hydraulic lift business in seconds, and submit a single RFQ form to contact multiple companies with your requirements.

Frequently Asked Questions About Small Hydraulic Lifts

What maintenance is required for small hydraulic lifts?

Routine maintenance includes checking hydraulic fluid levels, inspecting seals for leaks, lubricating moving parts, and ensuring safety systems (such as emergency stops and overload protection) are functional. Most manufacturers provide a maintenance schedule in the user manual. Regular inspections help extend lift lifespan and prevent downtime.

How do I determine the right size and capacity for my application?

Key considerations include the maximum load weight, required lift height, available installation space, and whether the lift will be stationary or mobile. Consulting with a supplier or manufacturer’s application specialist can provide tailored recommendations based on your specific use case.

Are small hydraulic lifts safe for personnel lifting?

Yes, when designed for personnel use and compliant with safety regulations. Look for models equipped with safety rails, non-slip platforms, emergency lowering valves, and certification to relevant standards (such as OSHA, ANSI, or CE). Always follow manufacturer guidelines and conduct operator training.

Can small hydraulic lifts be installed outdoors?

Many hydraulic lifts are suitable for outdoor use, provided they are constructed with weather-resistant materials and protective coatings. Discuss outdoor applications with your supplier to ensure your lift can withstand environmental exposure and temperature fluctuations.

What are the cost factors for small hydraulic lifts?

Costs depend on load capacity, lift height, platform size, power supply, safety features, and customization. Additional expenses may include installation, shipping, and ongoing maintenance. Request detailed quotes from multiple suppliers for accurate budgeting.

Where can I find more information or get a quote?

Browse our directory of hydraulic lift manufacturers for detailed company profiles, capabilities, and direct contact forms. For expert guidance, use our RFQ tool or reach out to our support team for personalized assistance.

Get Started: Find Your Ideal Small Hydraulic Lift Solution

Ready to invest in a reliable and efficient small hydraulic lift for your facility, workshop, or home? Explore our curated directory of leading hydraulic lift manufacturers to compare products, request quotes, or discuss your project with an industry expert.

Still have questions or need help choosing the best lift for your needs? Contact our team for personalized recommendations, technical support, or to schedule a consultation.

Empower your business or home with the safety, efficiency, and convenience of modern small hydraulic lifts—your trusted solution for ergonomic, space-saving, and dependable lifting applications.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services